The shoe-lasting machine is one of the oldest and most important pieces of equipment used in the shoemaking process. Invented centuries ago, the shoe-lasting machine has been used to shape and mold leather into durable and comfortable footwear.

The earliest shoe-lasting machines were made from wood and used to shape and stitch leather into the desired shape for the shoe. As technology advanced, more modern machines started to become available. By the early 20th century, machines made from metal and other materials had become more common. These machines allowed for the mass production of shoes, allowing the cost of production to be lowered significantly.

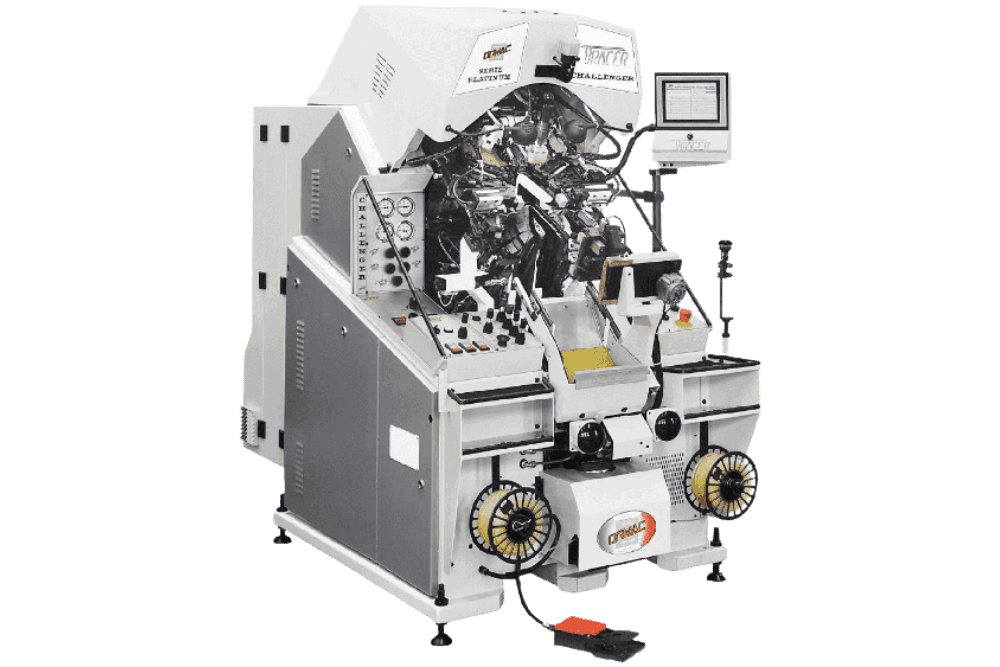

Today, the technology of the shoe-lasting machine has come a long way from its primitive beginnings. Modern shoe-lasting machines are now computer-controlled and capable of producing high-quality footwear at a rapid pace. These machines are currently used in almost every shoe manufacturing facility, allowing for the mass production of shoes at a much lower cost than ever before.

Shoe-Lasting Machines: Going Back to its Roots in the 1800s

Shoe-lasting machines have long been a staple of the footwear industry and have been used since the 1800s to help streamline shoe-making. Today, shoe-lasting machines are used to pull the upper section of a shoe over the last, and then nail it in place. This process is much faster and more efficient than it used to be when it was done by hand.

The first shoe-lasting machines were created in the 1800s when manufacturers began experimenting with new machines to help with the more labor-intensive parts of the shoe-making process. These machines were met with skepticism, as many people thought it would be impossible to replicate the manual process of lasting a shoe with a machine.

However, as manufacturers continued to develop the technology, more and more factories began to incorporate shoe-lasting machines into their production process. So, who put the potential of machines on the map?

Jan E. Matzeliger was born in 1852 in Suriname (then Dutch Guiana). He spent two years at sea before ending up in the United States, where he found a job in a shoe factory in Lynn, Massachusetts. He worked ten hours a day and spent his evenings learning English. He came up with the idea to build a machine that could handle the lasting of shoes—an element of shoemaking that was done manually and caused strife in the factory—, and he eventually succeeded.

How Did Jan E. Matzeliger Do It?

Jan Matzeliger was an inventor who changed the shoe industry forever. Born in the Dutch colony of Suriname in the mid-1800s, Matzeliger is credited with inventing the lasting machine, which allowed for the mass production of shoes.

Before Matzeliger’s invention, shoes were made by hand, and it could take up to three weeks to make a single pair. With his invention, Matzeliger was able to cut the time it took to make a pair of shoes down to less than an hour. His invention was revolutionary and allowed for the mass production of shoes, quickly revolutionizing the shoe industry.

Matzeliger’s patent application was initially rejected due to the complexity of the drawings, but after several attempts, he was eventually granted the patent. His machine could produce 200-700 pairs of shoes a day, a massive improvement over the traditional shoemaking methods.

Matzeliger’s patent had been sold to the Consolidated Lasting Machine Company prior to his passing in 1889. The company quickly grew and was soon merged with several other shoe machine manufacturers, forming the United Shoe Machinery Company. This company soon completely dominated the market for shoemaking machines with its complete solution of machine parks.

Unfortunately, Matzeliger died young due to tuberculosis and received very little recognition for his invention until recently due to his skin color. However, his invention has had a lasting impact on the shoe industry and will continue to do so for years to come.

The Bottom Line: Exploring the Evolution of Shoe-Lasting Machines

Shoe-lasting machines have been around for centuries, providing the essential step in the process of shoemaking. From the traditional wooden lasts used in the early days to the modern-day CNC-lasting machines used in the shoe industry today, the shoe-lasting machine has been an integral part of the shoe-making process.

Shoe-lasting machines are a testament to the ingenuity of the engineers who developed them. With their help, the process of lasting shoes has been revolutionized, allowing manufacturers to produce shoes with unparalleled accuracy and efficiency. Thanks to these machines, the footwear industry has been able to keep up with the ever-changing demands of the modern world.

If you’re in the market for shoe lasting machinery, look no further than American Shoe Machinery Company. With our wide selection of machines and our commitment to providing quality products, we’re the perfect choice for all of your shoe manufacturing needs.