Die Cutting Machinery

- Home

- Die Cutting Machinery

Electro-Hydraulic Crosshead Die Cutting Machine Type 2062

Electro-mechanic Roller Cutting Machine Type 7320

Hydraulic Die Cutter Type 6005BA

Electro-hydraulic Upstroke Cutting Machine Type 5230

Die Cutting Machine

When the phrase “die cutting” is used in casual conversation, the vast majority of listeners are clueless as to what this refers to in practice. One would be surprised to learn how widespread the use of professional die-cutting machines is, given the diversity of the fields that make use of them. The process of die cutting is best described as the utilization of a machine that applies pressure to cut finely detailed shapes out of a wide variety of materials utilizing a variety of different cutting tools. Paper, various kinds of textiles, and even leather are some of the materials that are most frequently used and may be understood with the least amount of effort. You can generate wonderful cutout pieces that are quite intricate by using a technique called die cutting, which is something that you would not normally be able to do with regular hand tools or non-specialized industrial manufacturing machines. A wide variety of designs, including outstanding footwork, can be embellished and decorated with the help of die-cutting machinery, which can also be used to program forms and cut them out using dies. When it comes to the production of the vast majority of shoe types, die-cutting technology is one of the most essential types of machines utilized today. In light of this, let us continue by providing a more in-depth explanation of what a professional die-cutting machine actually is.

Die cutters, also known as die-cutting machines, come in two sub-areas: those operated by hand, and their more modern counterparts that use electricity. In addition to electric die-cutters, manual motorized versions are also available. This is in contrast to digital or electronic ones, which need the use of a computer. Manual die cutters that are powered by motors or electricity still require human input. Instead of using a lever to activate the cutter, a button is used. Shapes are cut by applying pressure using a manual die cutter. To apply force between dies and die-cutting plates, these devices commonly employ a roller mechanism that is turned by a handle or crank. To cut out shapes, a digital die cutter will use blades or lasers that have been pre-programmed. They’re extraordinarily more complicated than traditional hand-operated die-cutters. The two are very different from one another, despite the fact that they both serve the same purpose of cutting out shapes. To generate a die cut, the main material is commonly positioned between two cutting plates and a die, using a manual die cutter. The dies and metal shims/cutting plates that go with these devices are useful in a wide variety of situations. Using a manual die cutter is as easy as positioning a die over a stamped image or piece of your chosen material and running it through the machine. Then layer them between the plates and run them through the machine for a precise slice.

Depending on the stroke speed, the feeding method, and the type of die-cutting machine, die-cutting can be a more efficient and speedier way to produce parts and components. In comparison to waterjet cutting and other blade-cutting methods, this one is significantly quicker. Die cutting’s speed, accuracy, and high quality more than makeup for its higher upfront cost. Die cutting is an easy method that can be used for mass production or smaller runs. The machine may be positioned right downstream from the process from which it is receiving the raw material in an industrial setting. The die-cutting machine’s many features make it a valuable tool. In addition to cutting, it is also capable of shaping, perforating, and scoring. Single or many strokes on a press are used to get the desired effect. Die-cutting machines such as flatbed, rotary, and semi-rotary models are typically used in factories because of their capacity to mass-produce complex pieces from thicker, more rigid substrates. Simultaneously, simple and supplementary components are made using manual and computerized die-cutting machinery. Its slower production pace makes it ideal for smaller orders.

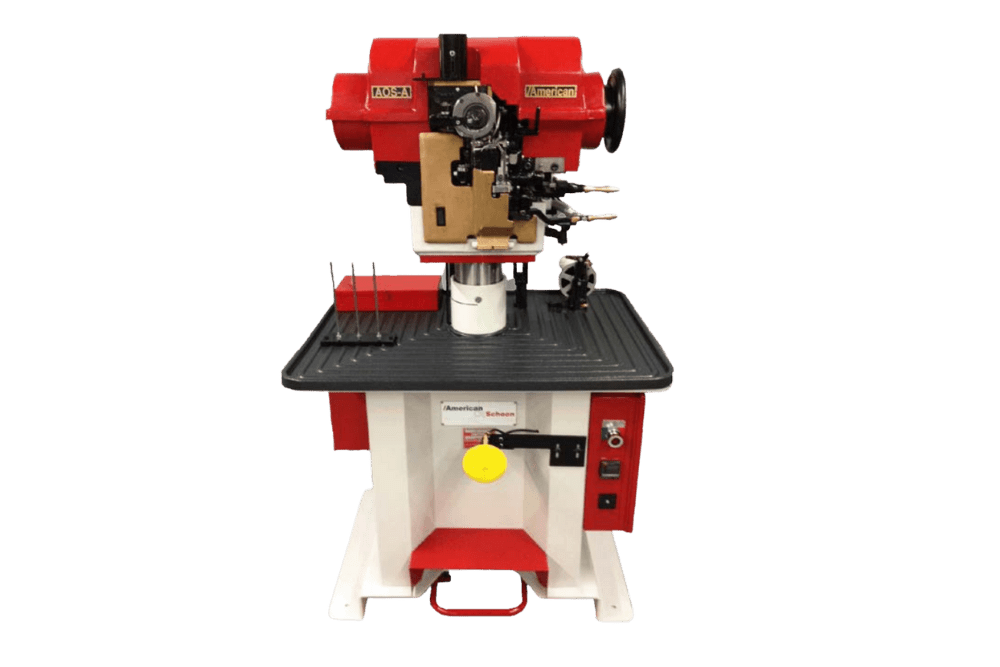

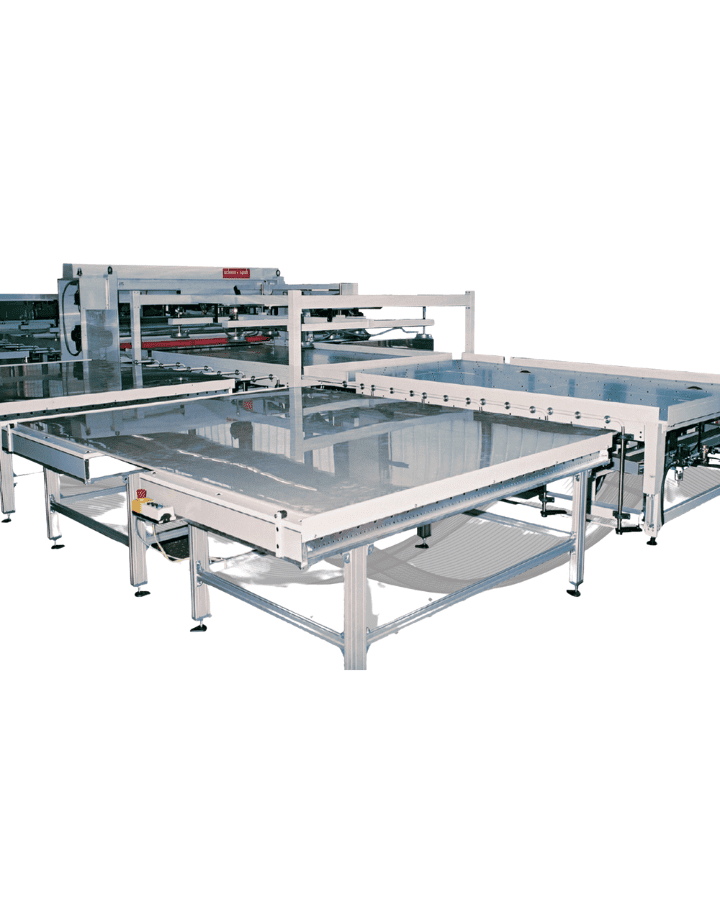

American Shoe Machinery Company our Die Cutting Machinery can be applied to a wide range of cutting applications as well as an array of industries such as abrasives, apparel, automotive, cardboard, carpet, envelope and paper, floor tiling, foam, footwear, gasket, leather, medical, packaging, roofing, rubber, textile and more. We also have cutting presses available that are wide-ranging, from standard swing beam presses to specialty designed large area or high pressure presses and everything in between. Below are some of the products we offer:

Swing Arm Clickers

- SA22 Swing Arm Clicking Machine

- 1028C Hydraulic Swing Arm Cutting Machine

Traveling Head Presses

- 2062 Electro-Hydraulic Crosshead Die Cutting Machine

- 2071bz Electro-Hydraulic Die Cutting Machine

- 7072c Electro-Hydraulic Crosshead Die Cutting Machine

- 7072m Electro-Hydraulic Crosshead Die Cutting Machine

- Allevi Quasar & Pulsar

Receding Head Presses

- 5300 Hydraulic Upstroke Cutting Machine with Receding Beam

- 5320 Hydraulic Upstroke Cutting Machine with Receding Beam

- 6005ba Hydraulic Die Cutting Machine

- 6050 Hydraulic Large Area Die Cutting Machine with Receding Beam

Large Area Presses

- 2070 Electro-Hydraulic Upper Piston Die Cutting Machine

- 5050 Hydraulic Large Area Die Cutting Machine

- 6050 Hydraulic Large Area Die Cutting Machine with Receding Beam

- *6140 Hydraulic Large Area Die Cutting Machine

Roller Cutting

- 7320 Electro-mechanical Roller Cutting Machine

Upstroke & Embossing

- 5230 Electro-Hydraulic Upstroke Cutting Machine