Packaging Industry

- Home

- Die Cutting Machinery

- Packaging Industry

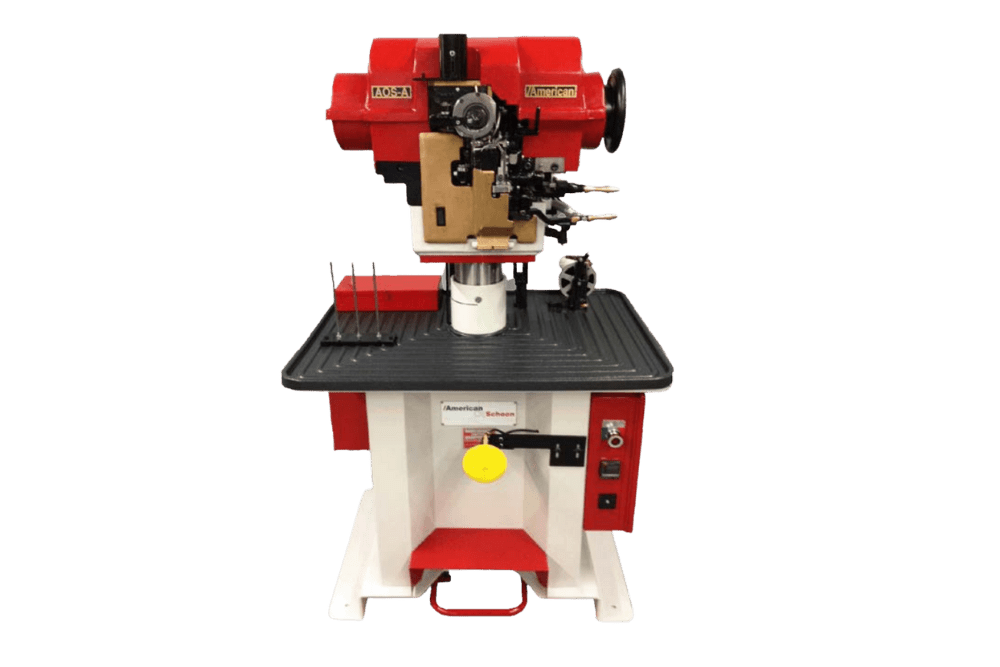

Electro-hydraulic Automatic Crosshead Die Cutting Machine, Model 2071BZ

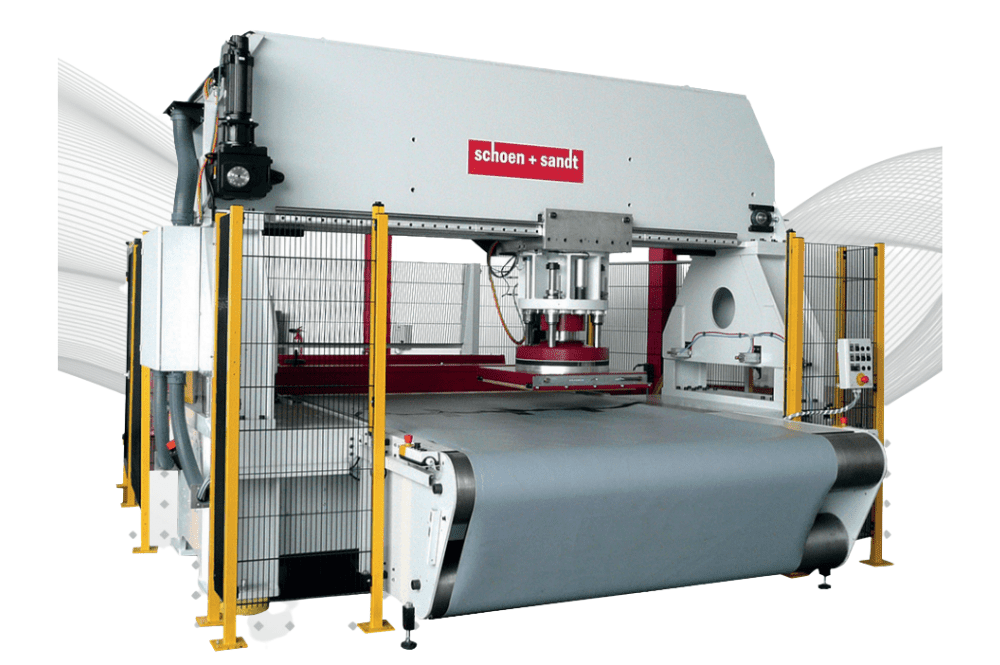

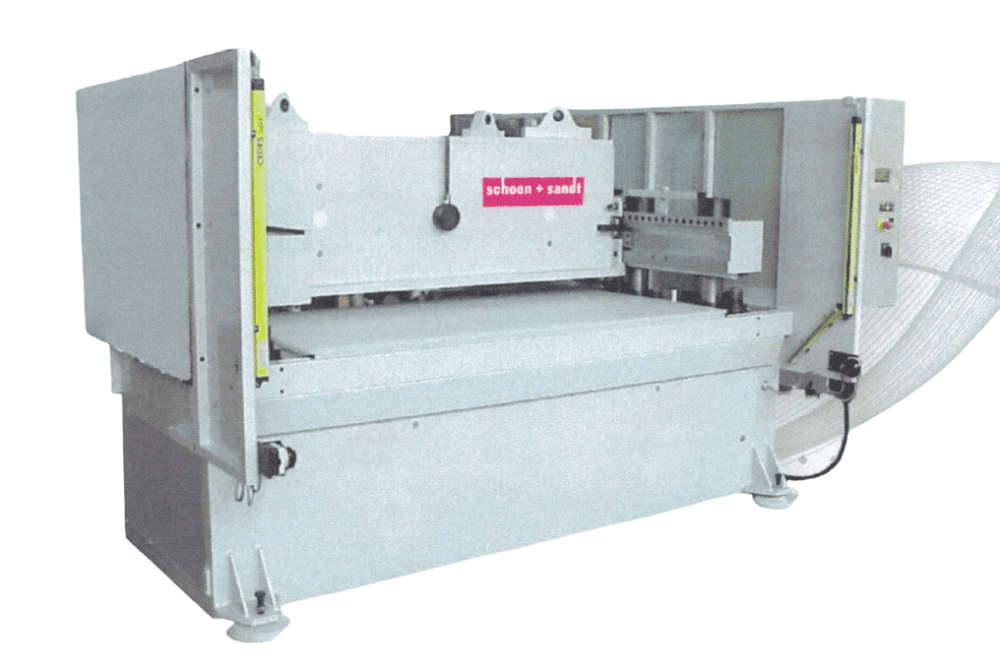

Hydraulic Large Area Die Cutting Machine, Model 5050

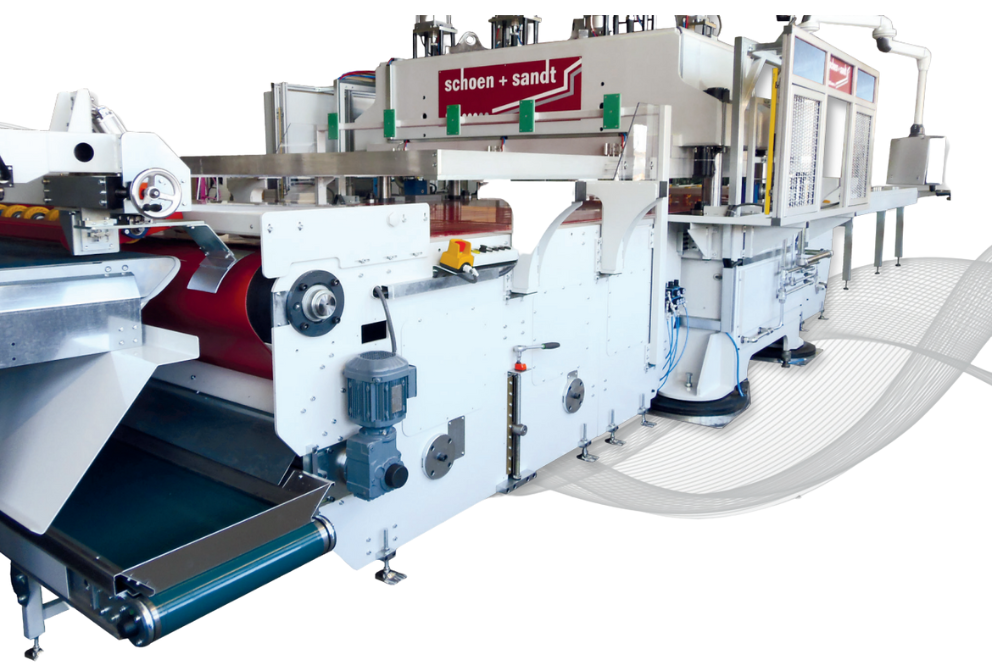

Hydraulic Large Area Die Cutting Machine with receding Beam, Model 6050

Die Cutting For Packaging

In the packaging sector, die-cutting is a common manufacturing technique. Chances are, unless you work in the packaging industry, you don’t have a solid understanding of what die-cutting entails. Originating in letterpress printing, die-cutting has developed into a highly specialized manufacturing technique. With the help of a die, packing materials can be fashioned into a wide variety of interesting forms and patterns through the die-cutting process. Most often, although not exclusively, it is employed in the production of folding carton packaging. Companies utilize die-cutting to make special packaging to fit their brand stories and improve the customer experience. Since it is simpler, quicker, and cheaper to build custom packaging in bigger quantities, the process benefits both manufacturers and businesses.

With the help of die-cutting, practically any shape, size, material, or fold can be applied to a package. The flexibility and variety of packaging features available to your business will be invaluable in the fulfillment process.

Unique, personalized packaging is now possible thanks to the die-cutting technique. Luxurious presentation in elaborate packaging adds a last touch of class that the buyer will remember. The die-cut design of custom packaging can be highlighted using a number of different finishing techniques. Consumers respond favorably to this renewed focus on packaging design, which should lead to increased sales in the future.

Die-cutting, as you can see, is a highly flexible method for precisely cutting, shaping, and printing your packaging, allowing for error-free repetition of the final product. Die-cutting is accurate and gives you many options for your store’s display. However, we are aware that not everyone is a printing and packaging whiz. Thankfully, here at American Shoe Machinery Company, that’s the case. Whether you have questions about the die-cutting process itself or how it will fit into your overall product packaging goals, we’re here to help! We even span to the roofing industry.

It’s okay if you want to sell a product with unique packaging but don’t know where to start. If you need carton boxes, corrugated boxes, or any other kind of branded packaging designed, our team of exceptional artists and engineers can do it for you.

It doesn’t matter if your package is made up of one piece or many, die cutting can be utilized on them all. It’s easy to add depth, drama, and precision to your messaging and experiences with multi-piece die-cut packaging designs. A paper or plastic sleeve is one type of secondary packaging that can be used in this way. Because the two layers are usually of different colors, the design “pops” when cuts are made in the outer layer, and the inner layer’s color is seen. Combining this die-cutting technique with conventional ink-on-paper printing creates a three-dimensional illusion that gives the box a more premium feel and look. A subtle, textured impression is achieved when the inner packing and exterior sleeve are the same color.

The die-cut forms of multi-layer die-cut packaging provide small glimpses into the inner layer, increasing the sense of mystery and anticipation surrounding the product inside. For dramatic films, this is the preferred option for the outside cover of the DVD case. This strategy can be quite effective at drawing in customers since it gives the impression that they are getting a glimpse of something they are not allowed to see.

The following machinery is available by us and suitable for the Packaging Industry:

Electro-hydraulic Automatic Crosshead Die Cutting Machine, Model 2071BZ

Hydraulic Large Area Die Cutting Machine, Model 5050

Hydraulic Large Area Die Cutting Machine with receding Beam, Model 6050