Medical Industry

Title

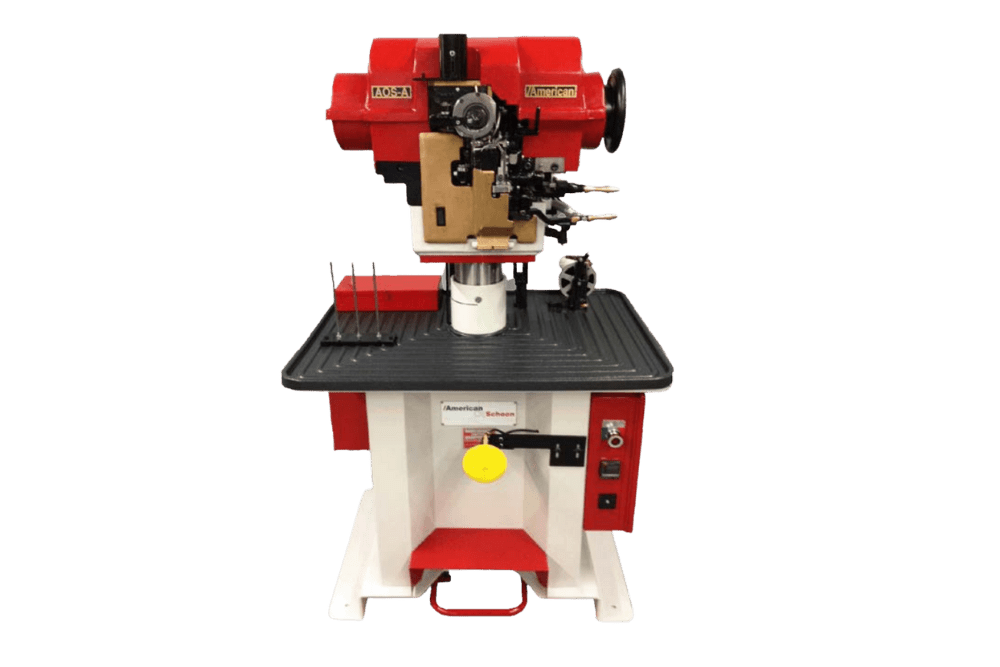

Hydraulic Automatic Die Cutting Machine, Model 2070

Title

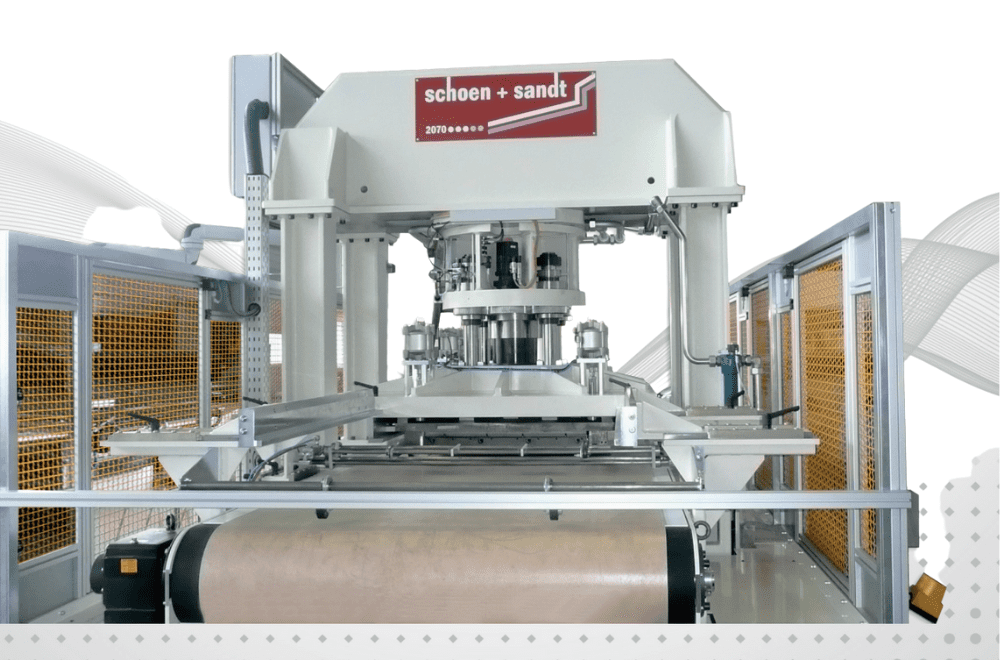

Electro-hydraulic Cutting & Embossing Press, Model 5230

Title

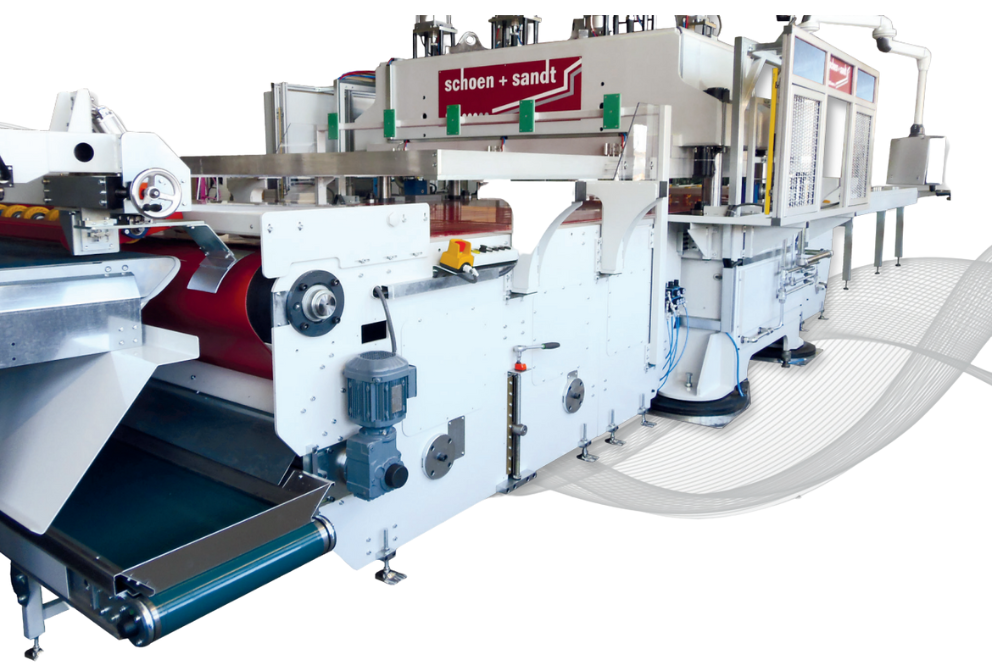

Hydraulic Large Area Die Cutting Machine, Model 5050

Title

Hydraulic Upstroke Cutting Machine with receding beam, Model 5300

Die Cutting For Medical Industry

Precision, uniformity, and increased safety are just a few of how die-cutting can improve the quality of components and products in the medical conversion and manufacturing industries. Another way die cutting boosts efficiency is by enabling the operator to cut several components in a single pass, which takes only a few seconds, and by making cleanup a breeze. Die cutting is utilized in the medical supply business to mass-produce custom, flexible medical-grade items, something that is not possible with more conventional production processes. If you’re in the medical supply industry, die-cutting is probably one of the methods you employ.

Because of our expertise, knowledge, and competitive prices, medical device companies frequently contract out their conversion needs to us. Researching the needs of the finished product and choosing the appropriate material is the first step in the medical die-cutting procedure. Then, factors like the volume, the needed level of presentation, the type of material and adhesive, and the tolerance of the material will need to be evaluated. After these factors are considered and it is determined that the necessary die cut can be manufactured, the appropriate machine and tool are chosen, and a prototype is made for review. After a trial run is completed and passed muster, the procedure can be expanded to meet demand. Depending on the intended use and the chosen process, the results of die-cutting can vary widely.

It is necessary to have access to high-quality manufacturing equipment in order to produce reliable and efficient medical supplies. Manufacturers need to educate themselves on the many processes that can assist them in meeting tough industry requirements so that they can remain competitive in the highly regulated and competitive manufacturing market of today. Die-cutting in medicine is a widespread procedure that can be found in many different kinds of hospitals. Die-cutting is an extremely well-liked process in the manufacturing industry. This is largely due to the fact that it is both effective and able to mass-produce identical products.

Precision and accuracy in medical die-cutting are essential, much like in the rubber industry for example. The sophisticated technology and cutting-edge materials required to produce these gadgets mean they come with a hefty price tag. Therefore, manufacturers must employ machinery and procedures with a small margin for error or risk incurring high costs. Precision and reproducibility are built into the die-cutting process. Different machines and materials will have different strengths and weaknesses, so manufacturers will need to compare them to choose the one that will deliver the best precision for their needs.

The healthcare sector is rapidly expanding, making it an important market for us. The medical device and medical disposable product industry rely on a wide variety of products and materials to maintain the high standards necessary to serve the industry. American Shoe Machinery Company can perform a wide variety of conversion services in-house, such as clean room die-cutting and converting, assembly, custom kitting, and packaging, as well as touchless digital cutting and rapid prototyping.

The following machinery is available by us and suitable for the Medical Industry:

Hydraulic Automatic Die Cutting Machine, Model 2070

Electro-hydraulic Cutting & Embossing Press, Model 5230

Hydraulic Large Area Die Cutting Machine, Model 5050

Hydraulic Upstroke Cutting Machine with receding beam, Model 5300