Shoe cementing and stock fitting are two essential aspects of shoemaking. Whether a DIY enthusiast or a professional shoemaker, understanding the basics of shoe cementing and stock fitting is crucial to ensure your shoes are comfortable, durable, and fit well.

Setting up a shoe factory requires careful planning and decision-making, and one of the most critical aspects of this process is selecting the right machinery and supplier for your business. The quality of the machines you choose and the reliability of the supplier you work with will significantly impact the success of your factory. Therefore, it is essential to consider several factors before making your final decision.

Assess Your Production Needs and Requirements

Before you start looking for machines and suppliers, it’s crucial to determine your production needs and requirements. Consider factors such as the type of shoes you’ll be manufacturing, the materials you’ll be using, and the production volume you’re aiming for. This information will help you identify the specific machines and equipment you need and make it easier for you to find a supplier that can cater to your requirements.

Research the Different Types of Shoe-Making Machines

Shoe manufacturing involves several processes, and each requires specialized machinery. Some of the common types of shoe-making machines include cutting machines, skiving machines, sewing machines, lasting machines, and finishing machines. It’s essential to understand the function of each machine and choose those that are most suitable for your production needs. Additionally, consider the level of automation and technology you want in your machines, as this will affect the efficiency and productivity of your factory.

Choose a Reputable and Reliable Supplier

Selecting a trustworthy and reliable supplier is crucial for the success of your shoe factory. Research different suppliers and ask for recommendations from industry peers to find a supplier with a good track record. Look for suppliers with experience in supplying shoe-making machines and a strong understanding of the industry. It’s also essential to choose a supplier that offers after-sales support, including maintenance and repair services, to ensure your machines remain in optimal condition.

Consider the Cost of the Machines

While it’s essential to invest in high-quality machines for your shoe factory, you also need to consider the cost. Compare the prices of machines from different suppliers and make sure to factor in any additional costs, such as shipping, installation, and training. It’s crucial to find a balance between quality and affordability when choosing machines for your factory.

Evaluate the Warranty and Support Services Offered by the Supplier

A reliable supplier should offer a warranty for the machines they sell. This gives you peace of mind and ensures that you’ll receive support in case of any issues with the machines. Apart from the warranty, consider the after-sales support services the supplier offers, such as maintenance, repairs, and spare parts availability. These services are crucial in keeping your machines running smoothly and minimizing production downtime.

Request for Machine Demonstrations and Training

Before finalizing your decision, ask the supplier to demonstrate the machines you’re interested in purchasing. This will give you a better understanding of how the machines work and help you assess their suitability for your production needs. Additionally, make sure the supplier offers training for your staff on how to operate and maintain the machines properly.

Consider the Lead Time for Machine Delivery and Installation

Lastly, consider the lead time for machine delivery and installation when choosing a supplier. This is particularly important if you have a tight production schedule and need the machines up and running as soon as possible. Choose a supplier that can guarantee timely delivery and installation to avoid any delays in your production process.

Conclusion

Selecting the right machines and suppliers for your shoe factory is a crucial decision that can significantly impact your business’s success. By considering the points mentioned above, you can make a well-informed choice that will help you establish a productive and efficient shoe factory. With the right machines and suppliers in place, you’ll be well on your way to building a successful shoe-manufacturing business.

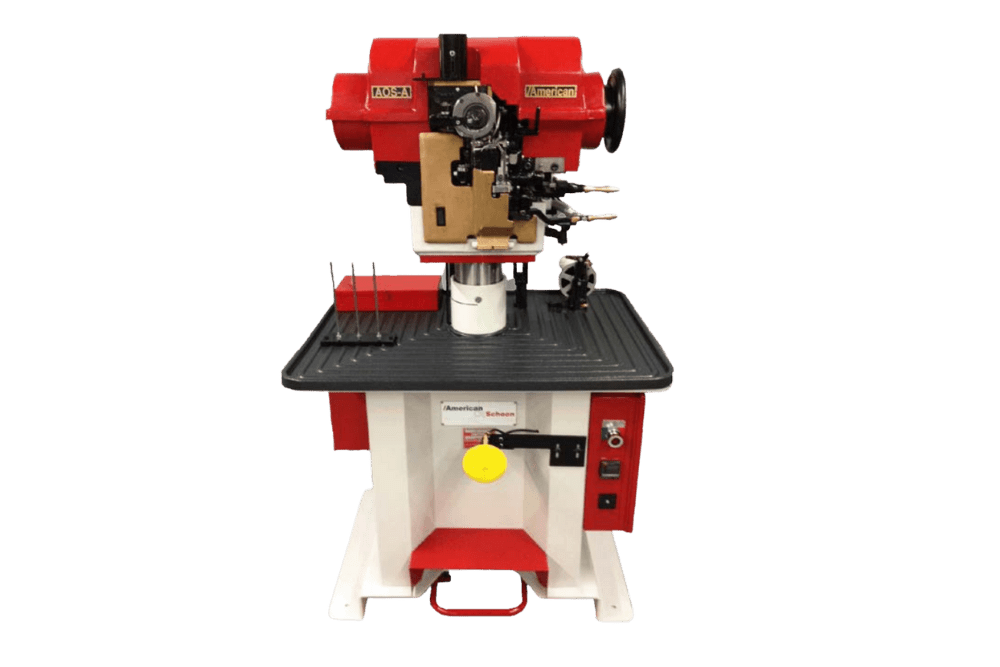

American Shoe Machinery Company is a renowned leader in providing die-cutting machinery and systems for various industries. If you are looking for die-cutting machinery for your shoe factory, reach out to us today!