Automotive Industry

- Home

- Die Cutting Machinery

- Automotive Industry

Swing Arm Clicking Machines, Models SA22, SA27 & SA27L

Electro-hydraulic Automatic Crosshead Die Cutting Machine, Model 2071BZ

Hydraulic Swing Arm Cutting Machine Type 1028C

Large Area Die Cutting Machine, Model 5050

Hydraulic Upstroke Cutting Machine with receding beam, Model 5300

Hydraulic Upstroke Cutting Machine with receding beam, Model 5320

Hydraulic Die Cutter, Model 6005ba

Hydraulic Large Area Die Cutting Machine with Receding Beam, Model 6140

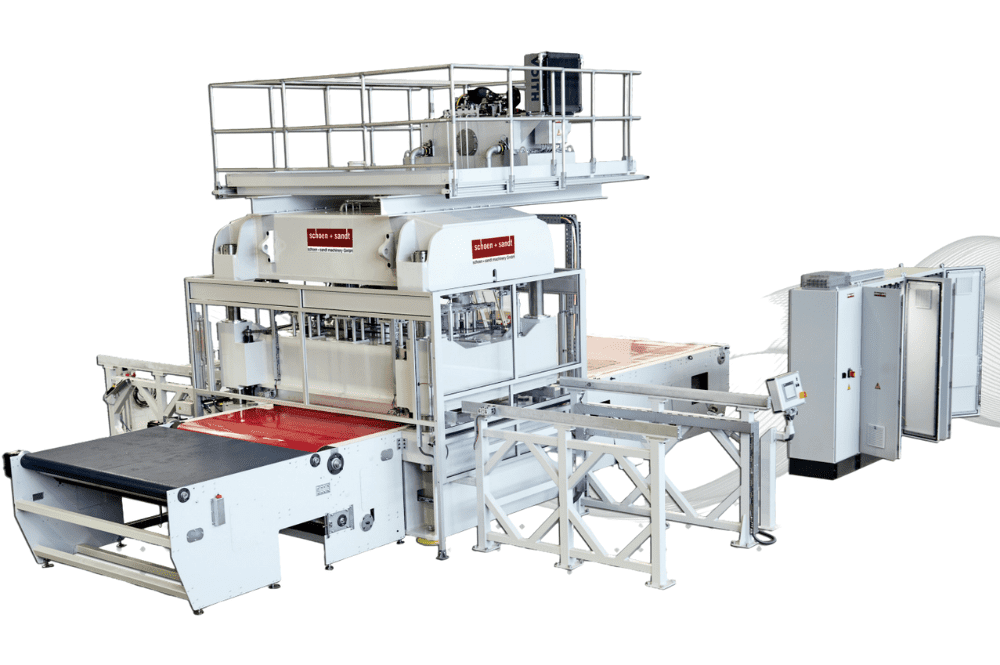

Automotive Industry Die Cutting Machine Equipment

In order to improve your value chain, American Shoe Machinery Company, a progressive die-cutter, can perform complex or time-consuming clip assembly procedures. Our expertise in automated clip assembly can free up personnel for use in more strategically important areas. Since we are involved in every step of the assembly process, we can make adjustments to the die-cutting methods and part presentation that would not be possible if we were starting with a box of pre-packaged die-cut components. The American Shoe Machinery Company can now cut dies and assemble clips in-house, eliminating the need to send both processes to third parties. The overall effectiveness of the supply chain benefits from the simplification of management.

The process of die cutting is widely used in industry to produce metal components that require a high level of accuracy. The term “die cutting” refers to the use of a die, a specialized tool used in a press to shear webs of weak materials. Rubber, fabric, paper, plastic, and metal are just some of the many substrates that can be cut with a die. The first step in the die-cutting process is to design a custom die to cut the part to the exact specifications. Die design is crucial to a project’s overall success, and many manufacturers are now using automated software to design more precise dies. The blades of a die are positioned in such a way as to produce the desired shape of the component. After the necessary form has been given to the die, it is attached to a plate and placed in the press (which may be rotational or flatbed in design). The manufacturer places the material on the press and presses it with the die until the die takes the desired shape. The die is adaptable and can be used with various materials to create a variety of different shapes. Due to its many uses across many different industries, die-cutting has remained one of the most popular manufacturing techniques.

The use of die-cutting in the production of commonplace goods is increasing in importance. Because it can be used with so many different metals, die-cutting allows manufacturers to create high-quality, fashionable goods without increasing production costs or decreasing profit margins.

The following machinery is available by us and suitable for the Automotive Industry:

Hydraulic Swing Arm Cutting Machine,Model 1028C

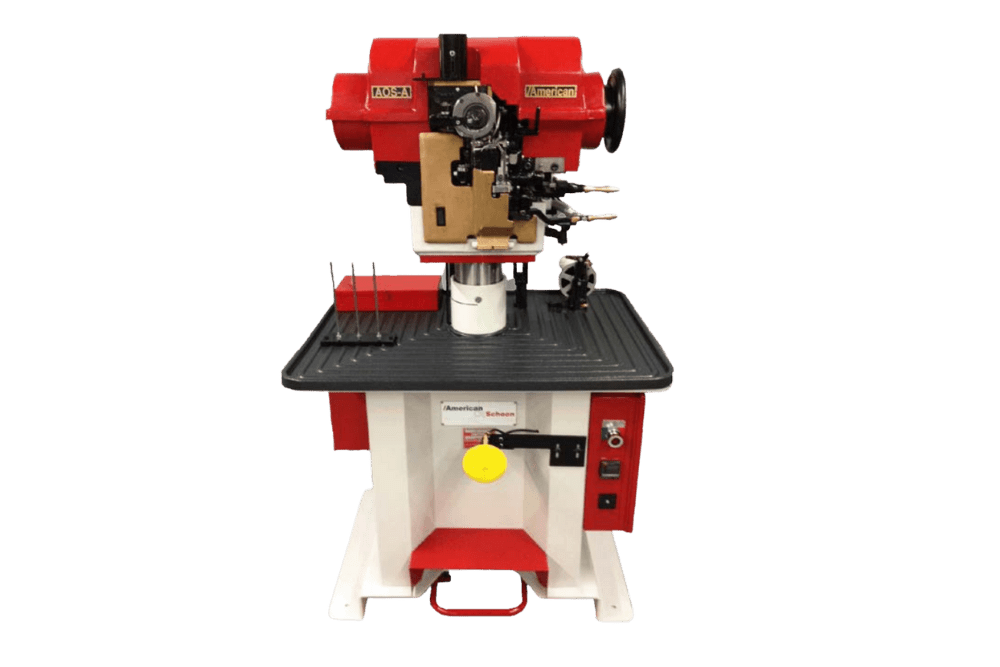

Swing Arm Clicking Machines, Models SA22, SA27 & SA27L

Electro-hydraulic Automatic Crosshead Die Cutting Machine, Model 2071BZ

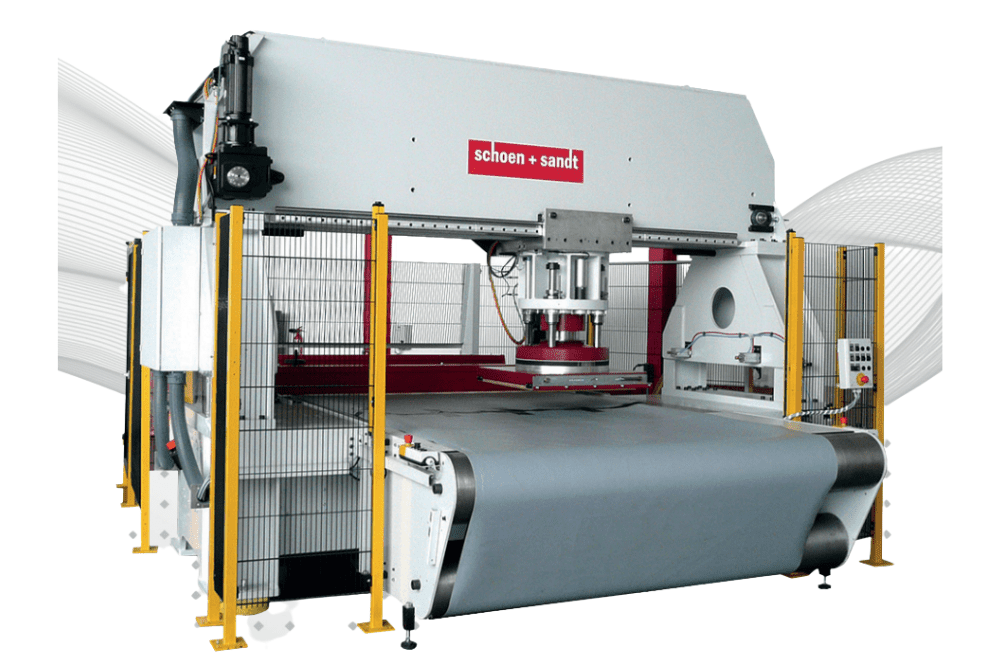

Large Area Die Cutting Machine, Model 5050

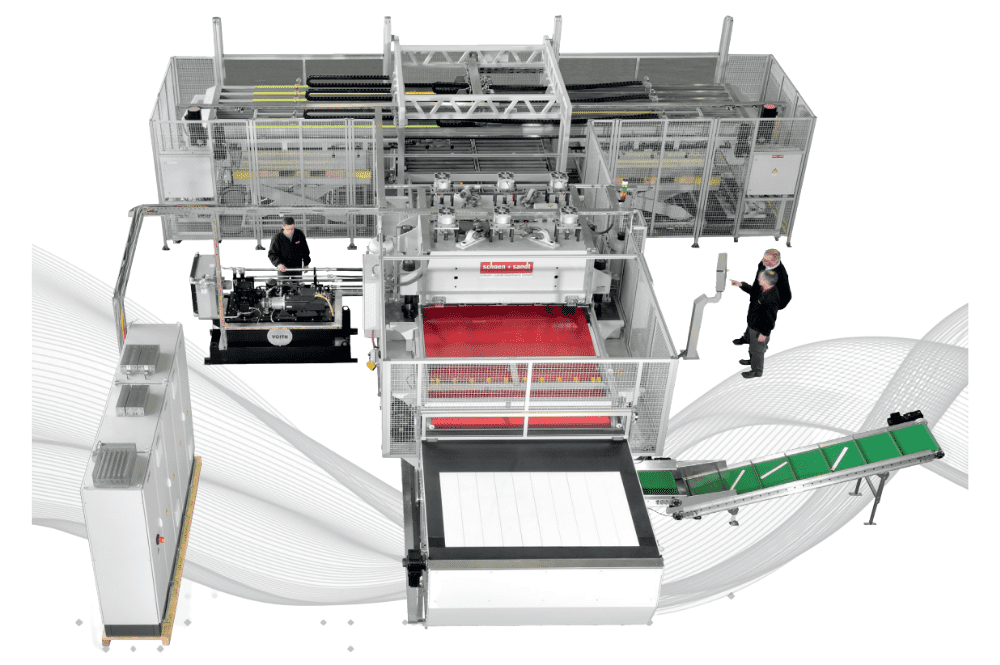

Hydraulic Upstroke Cutting Machine with receding beam, Model 5300

Hydraulic Upstroke Cutting Machine with receding beam, Model 5320

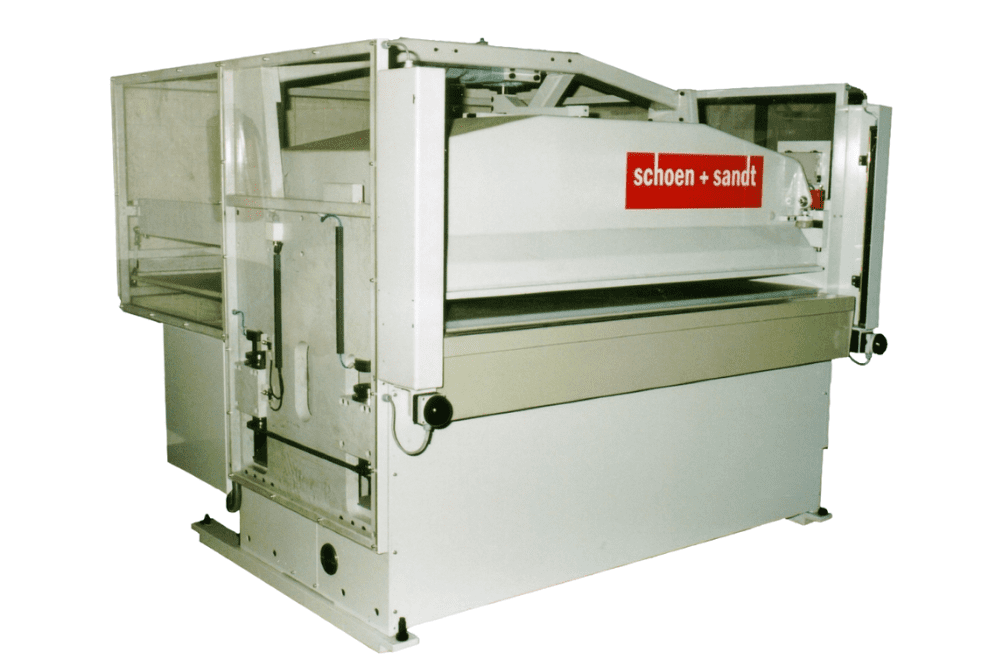

Hydraulic Die Cutter, Model 6005ba

Hydraulic Large Area Die Cutting Machine with Receding Beam, Model 6140*