Foam Industry

- Home

- Die Cutting Machinery

- Foam Industry

Title

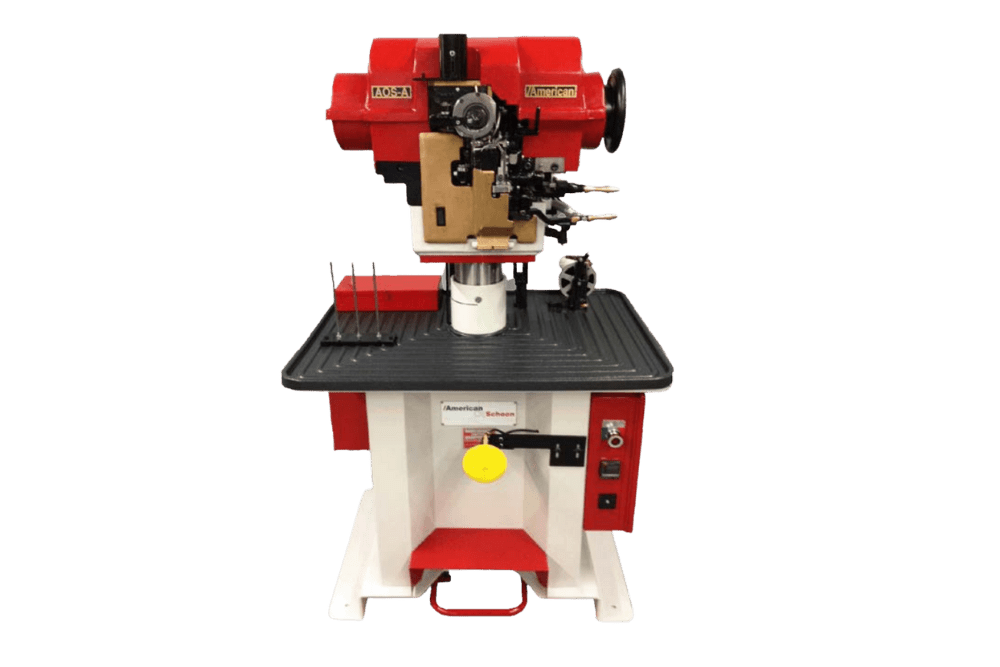

Swing Arm Clicking Machines, Models SA22, SA27 & SA27L

Title

Hydraulic Swing Arm Cutting Machine, Model 1028C

Title

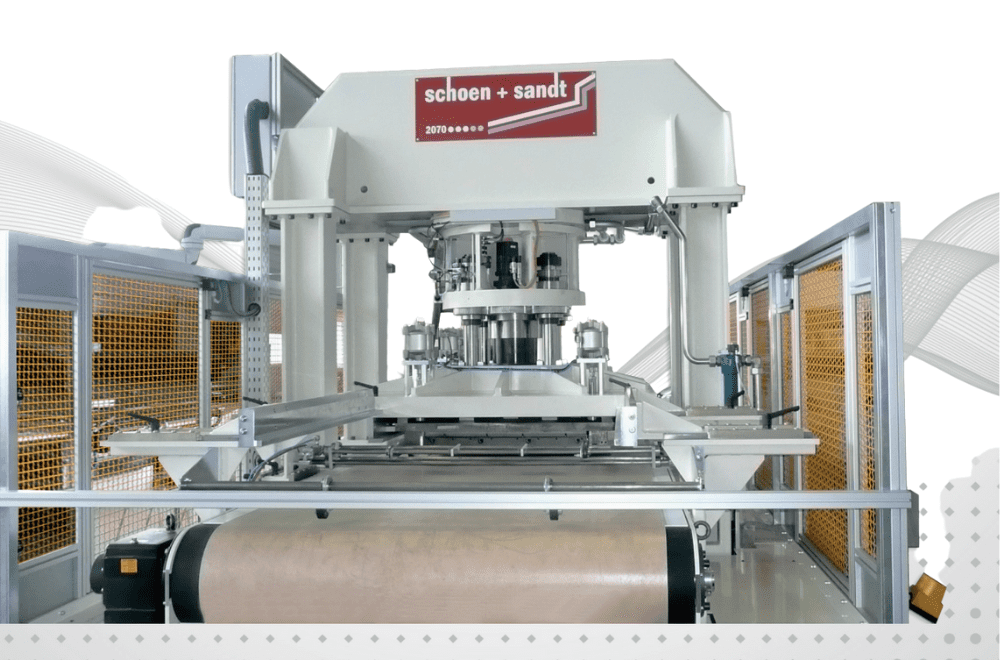

Hydraulic Automatic Die Cutting Machine, Model 2070

Title

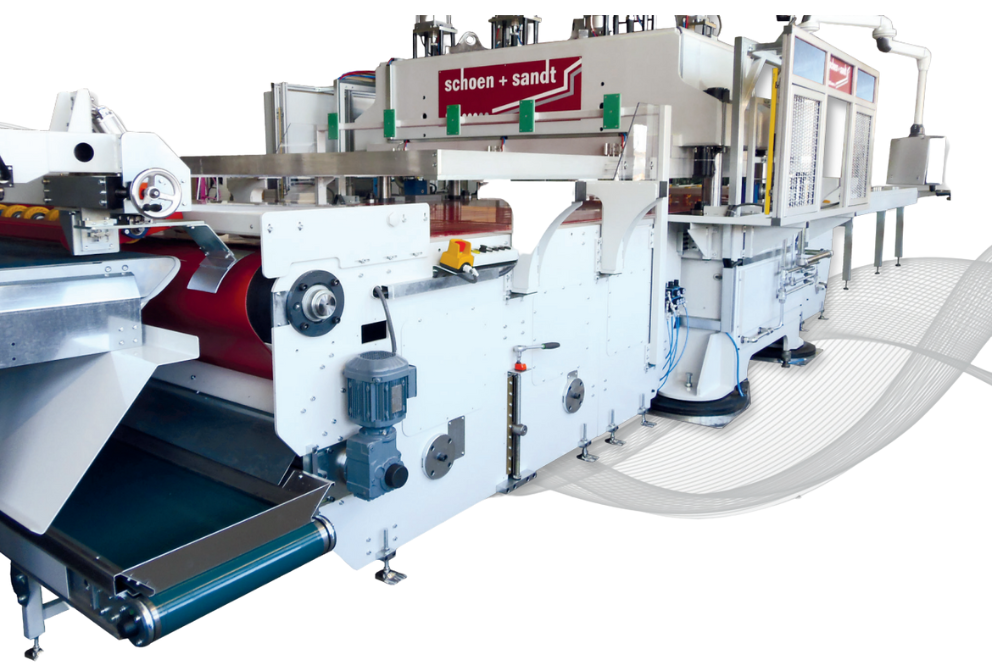

Electro-hydraulic Automatic Crosshead Die Cutting Machine, Model 2071BZ

Title

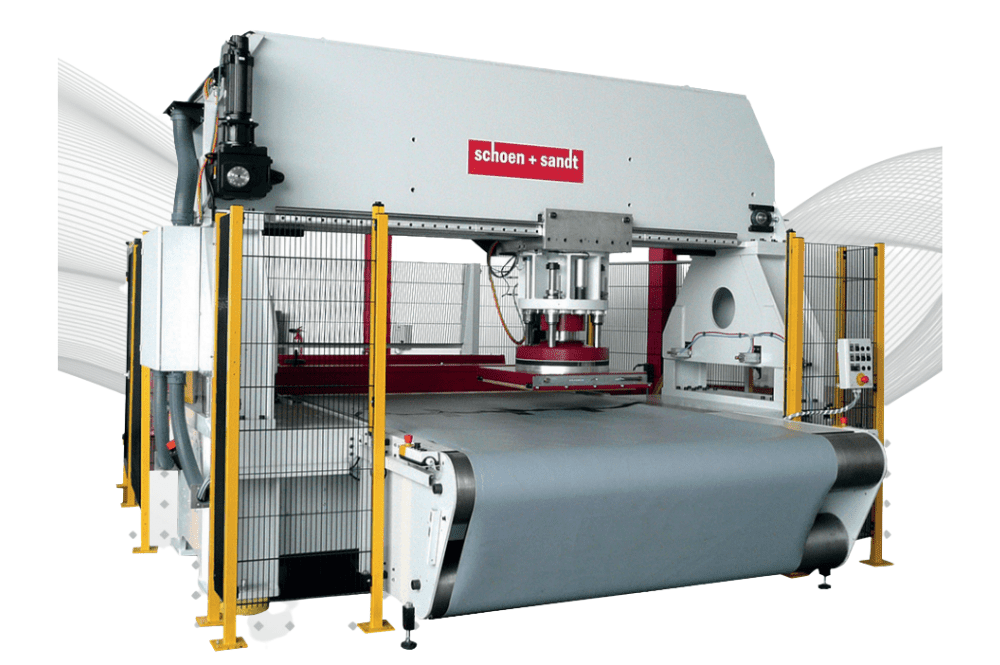

Large Area Die Cutting Machine, Model 5050

Title

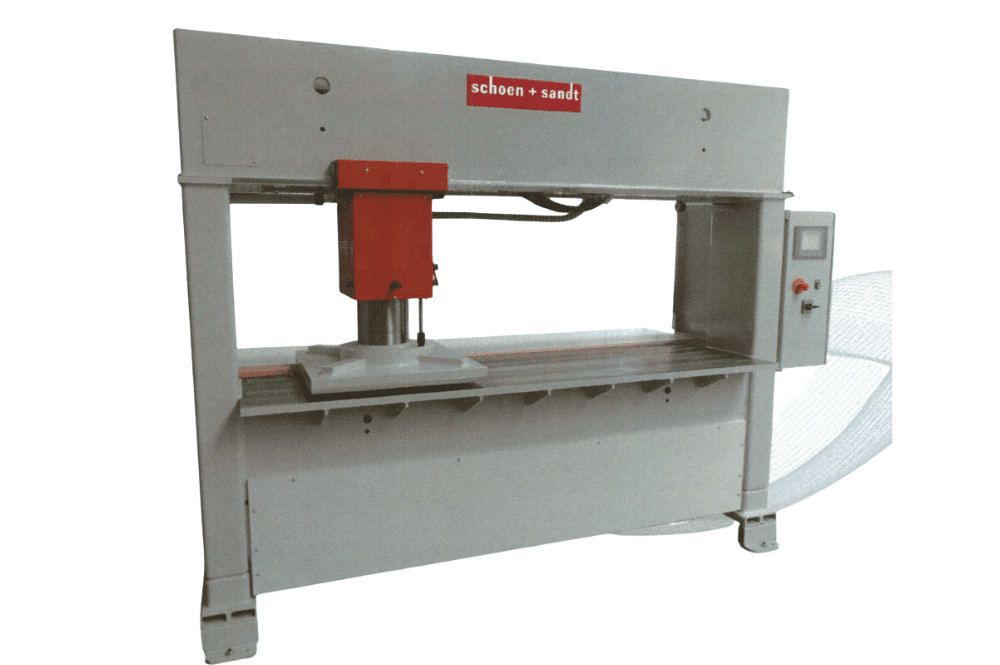

Electro-hydraulic Cutting & Embossing Press, Model 5230

Title

Hydraulic Upstroke Cutting Machine with receding beam, Model 5300

Title

Hydraulic Upstroke Cutting Machine with receding beam, Model 5320

Title

Electro-hydraulic Crosshead Die Cutting Machine, Model 7072M

Title

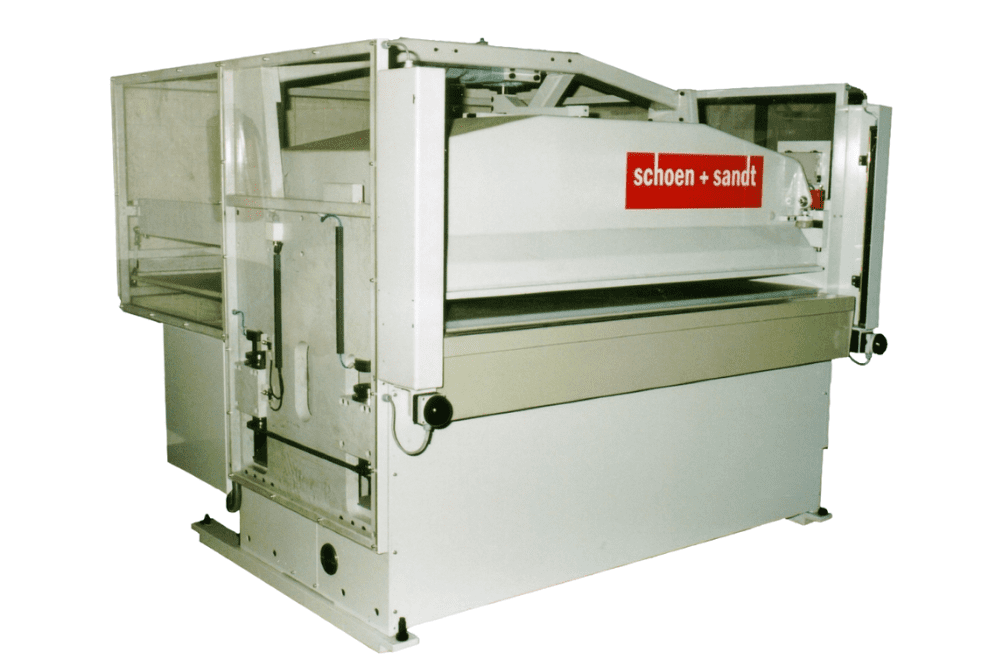

Hot Melt Roll Coater for Foam, Model Termo 610

Die Cutting For Foam

Foam is a versatile substance with several useful functions. The key to a useful product is not just selecting the appropriate foam, but also having it manufactured to your precise requirements. Our foam die-cutting press allows us to provide you with the high-quality, precisely cut foam you want.

Our die cutter is essentially a giant cookie cutter, making it ideal for precisely cutting out shapes from foam. Thin, finely serrated blades are inserted into wooden blocks to make dies, also called plates. Foam sheets are laid over the plates and subjected to compression forces of up to 80 tons. By pressing down on the foam and then releasing it over the blades, a shape is formed that precisely matches the image on the plate. The risk of inadvertent use is considerably reduced by the die cutter’s simultaneous two-button safety mechanism, which is necessary to carry out a pressing.

The die cutter is most commonly used for mass production because of its capacity to manufacture multiple forms with a single pressing. The die cutter can produce thousands of identical parts in a fraction of the time it takes the waterjet machine to produce hundreds. The die cutter is used to make novelties and toys like the gigantic foam hands seen at sporting events, as well as detailed high-volume requirements like form-fitting wrapping for sensitive objects. Our foam die-cutting equipment and premium materials make it simple and affordable to get the precisely cut product you require. Precision is needed in this industry, just as it is needed in the gasket industry. Let us use this dependable device to make you something right now!

American Shoe Machinery Company provides die-cutting services for foam, catering to your particular requirements. Many of our punch presses have the capability to kiss cut, which is a technology that is utilized in situations in which pressure-sensitive adhesives are utilized. This technology enables finished components to be pulled off the release liner, which in turn automatically exposes the adhesive. Because our largest press makes use of a traveling head technology, we are able to employ whole sheets of raw materials (both open and closed cell), which eliminates the need for any preparatory processes, which in turn saves both time and money.

Foam components can be stamped out with a die-cutting technique by employing steel ruled instruments, or “dies,” and a punch press. Die-cut foam can be made into any two-dimensional shape using several types of punch presses. Die-cut foam end caps and protective foam package components are only two examples of what may be made using this method.

With the help of dies and specialized blades, the foam may be cut into any desired form or size. In order to make the foam more flexible and manageable, it is usually heated or otherwise softened. Pushing the foam between two heated dies causes the blades to score, slice, or perforate the foam as it is being molded. The resulting die-cut foam has many uses, including packing and insulating products. The process’s precision enables the creation of elaborate designs on even relatively thin sheets of foam, making it a useful material for a wide variety of applications. Die cutting is a simple and efficient method for modifying foam materials into unique forms and structures.

The following machinery is available by us and suitable for the Foam Industry:

Swing Arm Clicking Machines, Models SA22, SA27 & SA27L

Hydraulic Swing Arm Cutting Machine, Model 1028C

Hydraulic Automatic Die Cutting Machine, Model 2070

Electro-hydraulic Automatic Crosshead Die Cutting Machine, Model 2071BZ

Large Area Die Cutting Machine, Model 5050

Electro-hydraulic Cutting & Embossing Press, Model 5230

Hydraulic Upstroke Cutting Machine with receding beam, Model 5300

Hydraulic Upstroke Cutting Machine with receding beam, Model 5320

Electro-hydraulic Crosshead Die Cutting Machine, Model 7072M

Hot Melt Roll Coater for Foam, Model Termo 610