Apparel and Textile Industry

- Home

- Die Cutting Machinery

- Apparel and Textile Industry

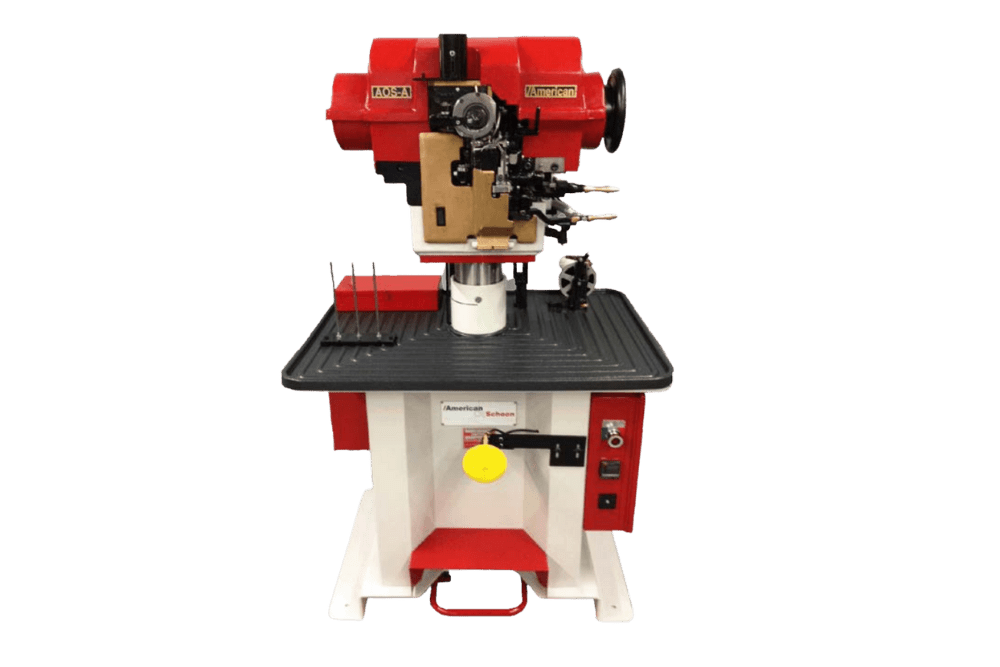

Swing Arm Clicking Machines Model SA22, SA27 & SA27L

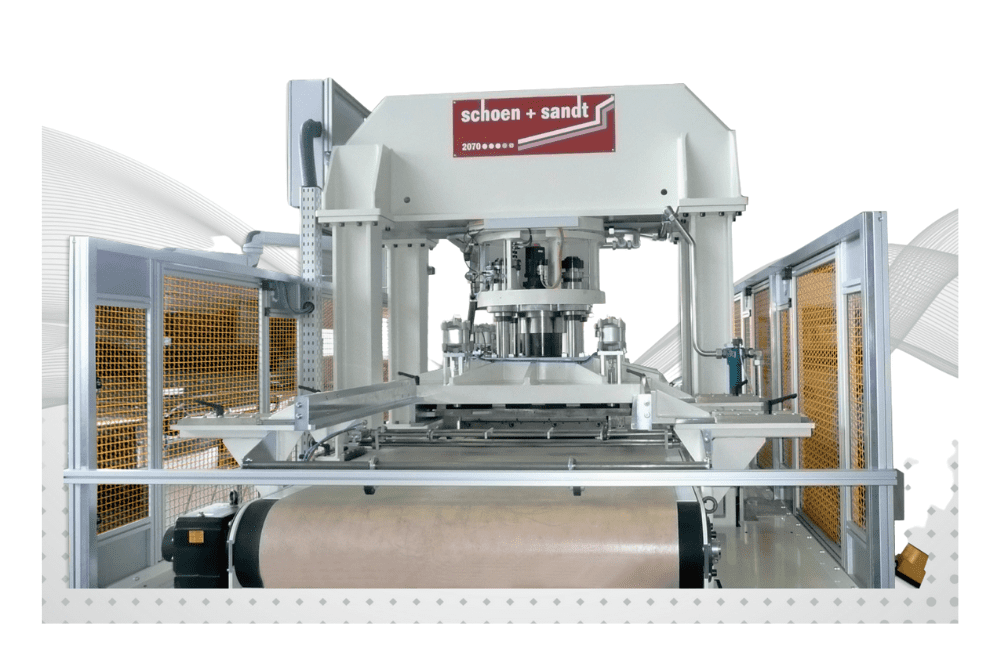

Electro-hydraulic Upper Piston Die Cutting Machine Type 2070

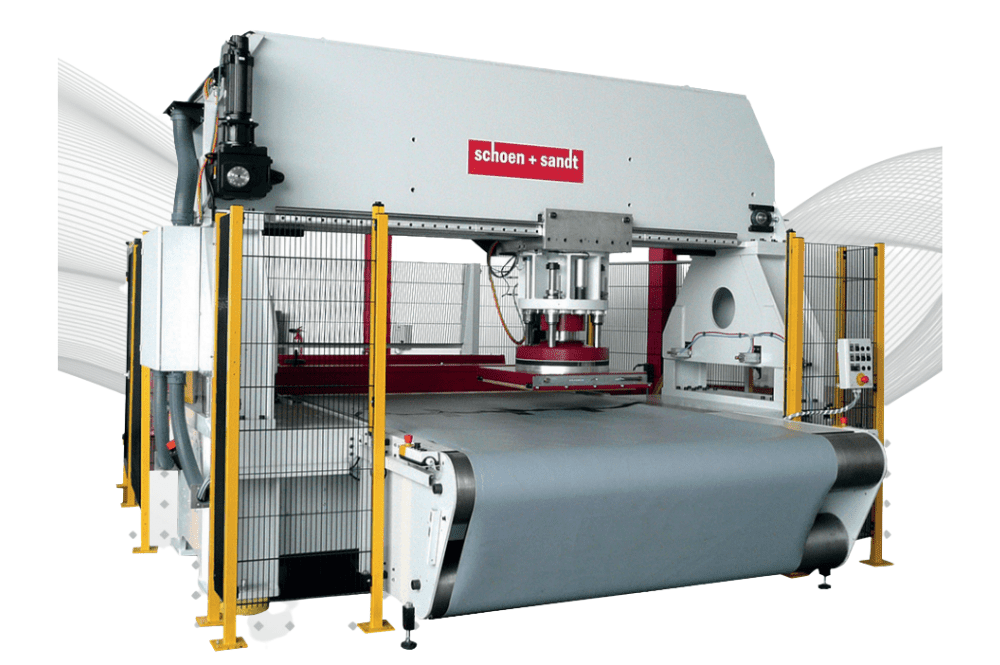

Electro-hydraulic Automatic Crosshead Die Cutting Machine, Model 2071BZ

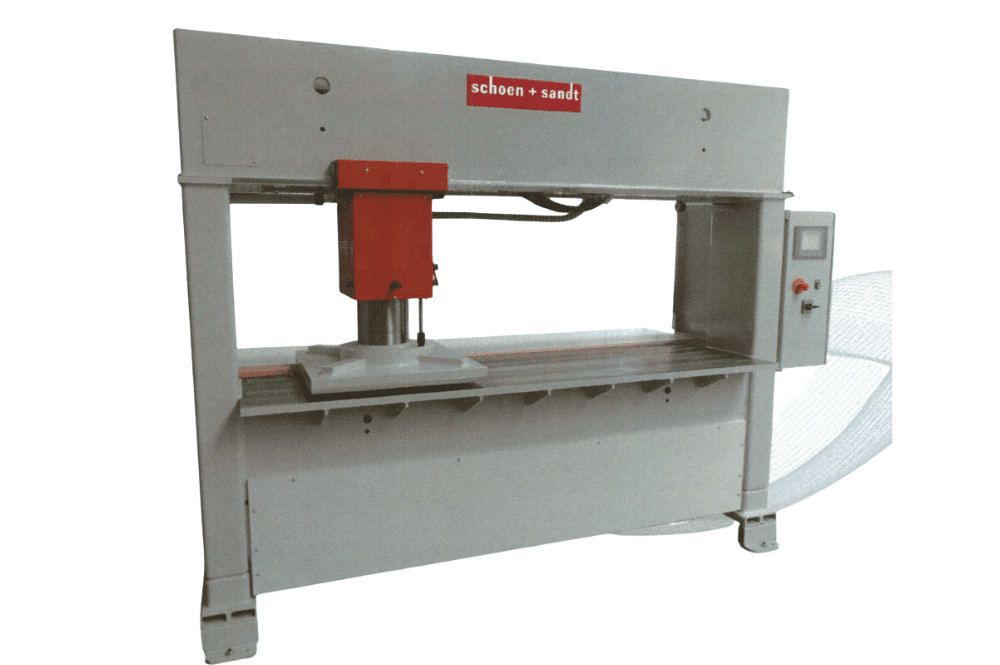

Electro-hydraulic Crosshead Die Cutting Machine, Model 7072M

Apparel and Textile Machine Equipment

Fabric die-cutting is a method that is both quick and precise for cutting block components. Die blades are made of sharp metal and are fixed onto a board with a protective foam surround. Die sets feature one color of foam for the components that are going to be cut, another color of foam for the excess fabric, and a metal blade in the middle. This is designed to make it easier to put the fabric. After placing as many as six layers of fabric on the die and placing a protective cutting board on top of the fabric, the assembled components are then fed into a die-cutting machine, which cuts out the desired shape.

Die-cutting is fantastic for cutting block components that are not easily cut by rotary cutting. Additionally, die-cutting makes it easy to cut multiples of a single shape, and it is helpful for individuals who have difficulty rotary cutting. The benefits of fabric die-cutting include the following: it saves time because one can cut up to six layers at once; accuracy in die-cutting improves accuracy in piecing; accuracy in die-cutting improves accuracy in piecing; die-cutting is great for cutting block components that are not easily cut by rotary.

When you need to cut out a shape that would be difficult or impossible to achieve with a rotary cutter, investing in a fabric die-cutting machine is a wise choice. When cutting many identical strips or simple designs like many identical squares, these devices offer a huge time saver. These machines make cloth cutting easier for those with limited mobility. Fabric placement markings can be made on the foam. Be sure to stagger the fabric or die as you feed it into the Fabric Die-Cutting machine. This will ensure a smoother passage through the machine.

A die-cutting machine will save Quilters time and cut shapes precisely. Die-cutting machines may be unfamiliar to you. Remove creases first. Before die-cutting, iron out wrinkles and creases. The wrinkle-free fabric ensures precise cutting. Avoid skipping this step. Jagged cuts may result. Prepare the machine. After preparing the fabric, prepare the machine. Level your machine. Place the fabric on your die. The fabric should match the blade angle. Place the mat over the fabric.

You can use a mat larger than the fabric, but it must entirely cover it. Cut your fabric. After setting up the machine, turn the handle with one hand while carefully guiding the folded fabric, die, and mat to the middle. Once the rollers grab the die, cease directing the sandwich. Keep cranking. Rollers press the die to cut the fabric as the sandwich passes. Fabric is cut after the sandwich rolls through. A stylus can remove fabric from the dye. Avoid accidentally poking your finger into a blade. Repeat until you’ve cut all your project’s fabric. Use many layers of cloth to cut multiple pieces of the same shape. Die-cutting machines are simple to operate and will save you time on jobs which is why we also serve other industries such as the automotive industry.

The following machinery is available by us and suitable for the Apparel and Textile Industry:

Swing Arm Clicking Machines, Models SA22, SA27 & SA27L

Hydraulic Automatic Die Cutting Machine, Model 2070

Electro-hydraulic Automatic Crosshead Die Cutting Machine, Model 2071BZ

Electro-hydraulic Crosshead Die Cutting Machine, Model 7072M