Die Cutting Belts

Polyurethane Die Cutting Belts

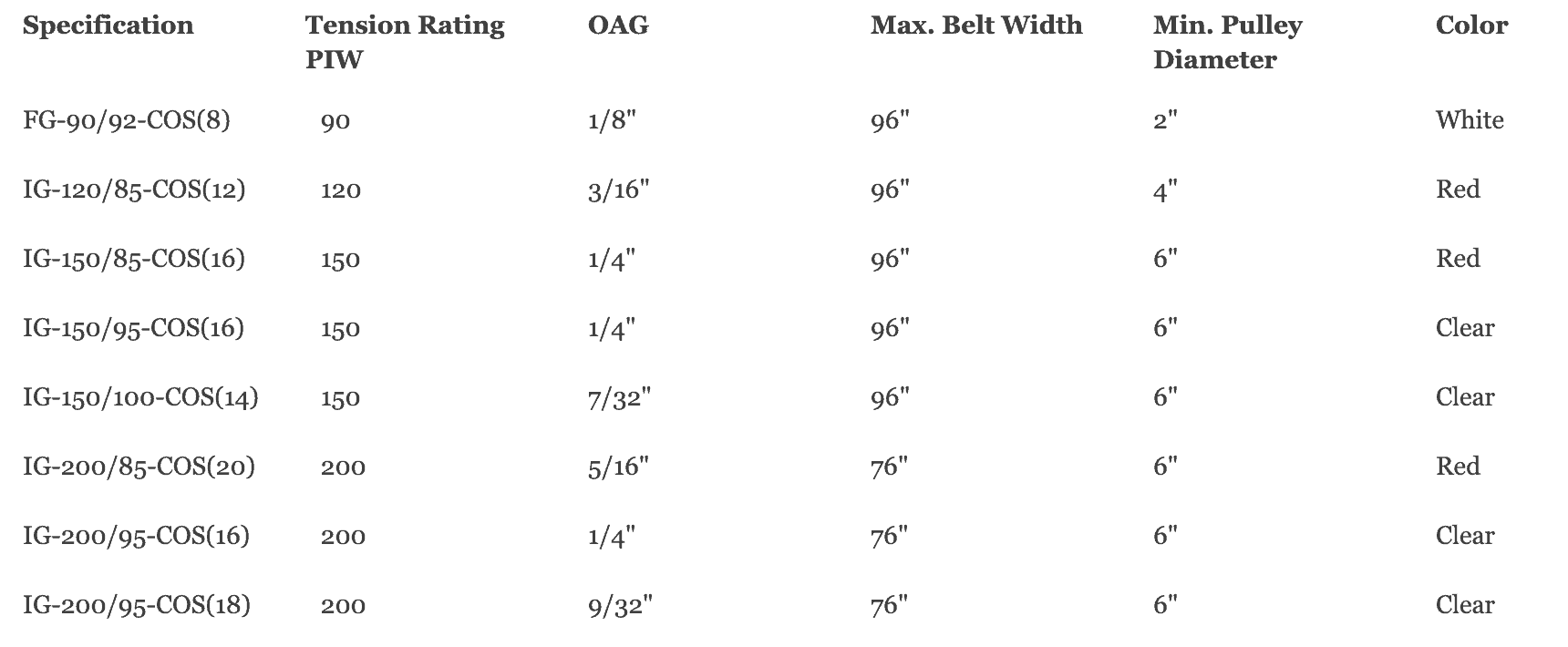

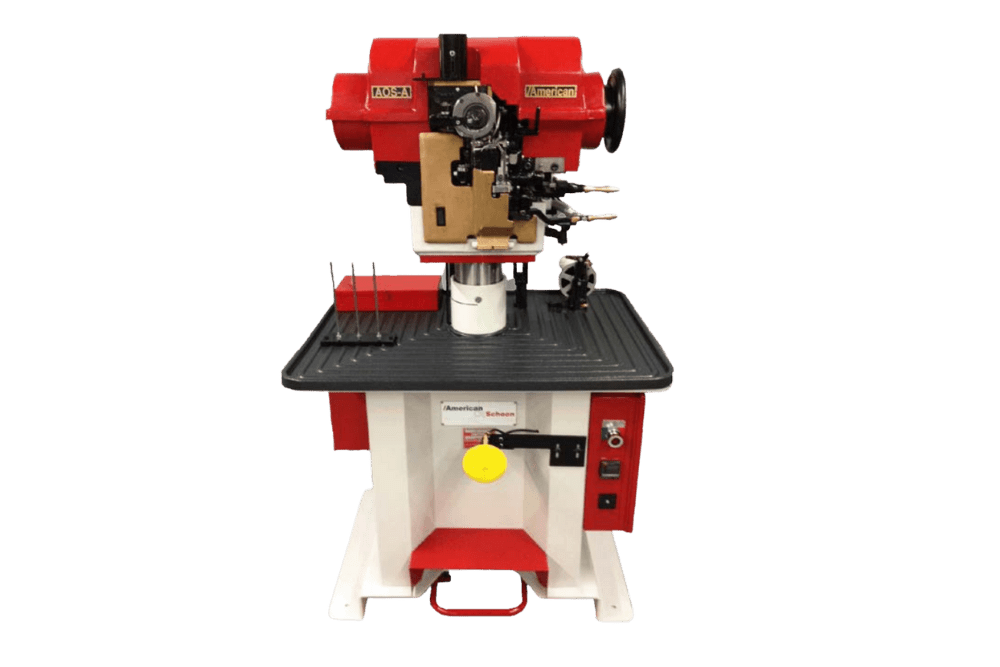

At American Shoe Machinery Company we offer a unique line of thermoset polyurethane die cutting belts used in our Schoen + Sandt Die Cutting Machines as well as on all the other brands of die cutting presses. Specially formulated 85, 92, 95 and 100 Durometer, Shore A Hardness cutting surfaces are designed to provide significant cut resistance and cost effective service life. While the 85 durometer is the most popular, the 100 durometer (50 Shore D) provides the ultimate cut resistance. The polyurethane saturated belt carcass enhances the belt’s integrity, while providing a low coefficient of friction on its bottom surface making it ideal for slider bed service. The 90 PIW, 120 PIW and150 PIW fabricsare now available in widths of up to 96”and the 200 PIW fabric is available in widths of up to 76” without longitudinal splice

These polyurethane Die Cutting Belts with their inherent thermoplastic properties can be spliced endless and tears or accidental die cuts can be repaired simply by utilizing a weld rod and a hot air gun. This feature, which is not applicable to the other thermoset urethane or nylon die cutting belts, significantly reduces downtime and lost production.

Precision ground die cutting belts to a thickness tolerance of +/-.003” are available on all specifications with a maximum width of 80”.

Features

- Specifically formulated cut resistant thermoset urethane belt covers in 4 different hardnesses

- Available in widths up to 96” without a longitudinal splice

- Can be quickly spliced endless or repaired with a hot air welding procedure