Paper Industry

Title

Swing Arm Clicking Machines, Models SA22, SA27 & SA27L

Title

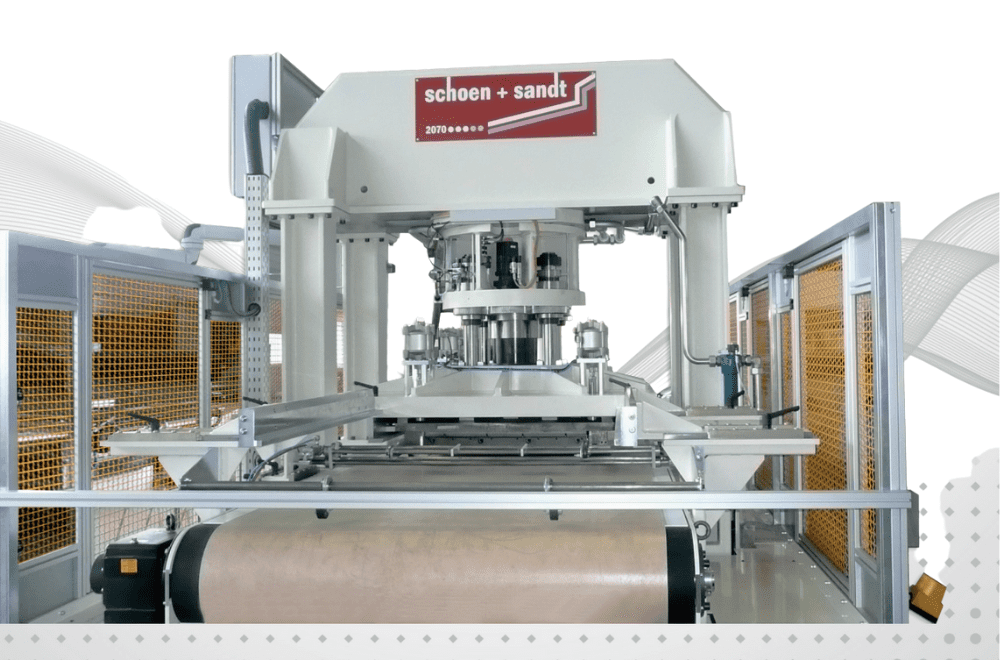

Hydraulic Automatic Die Cutting Machine, Model 2070

Title

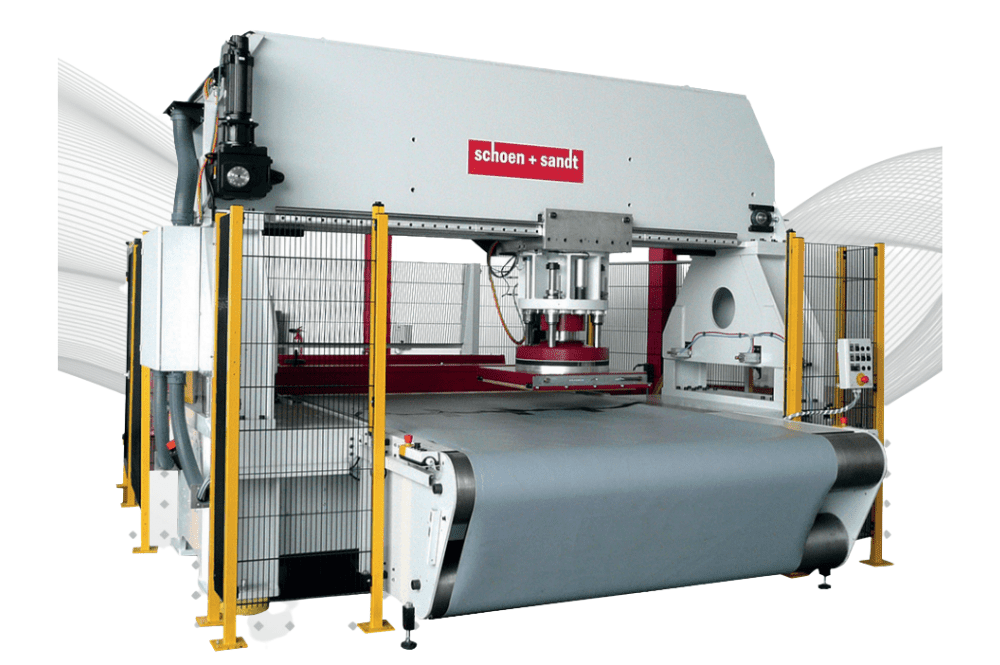

Electro-hydraulic Automatic Crosshead Die Cutting Machine, Model 2071BZ

Title

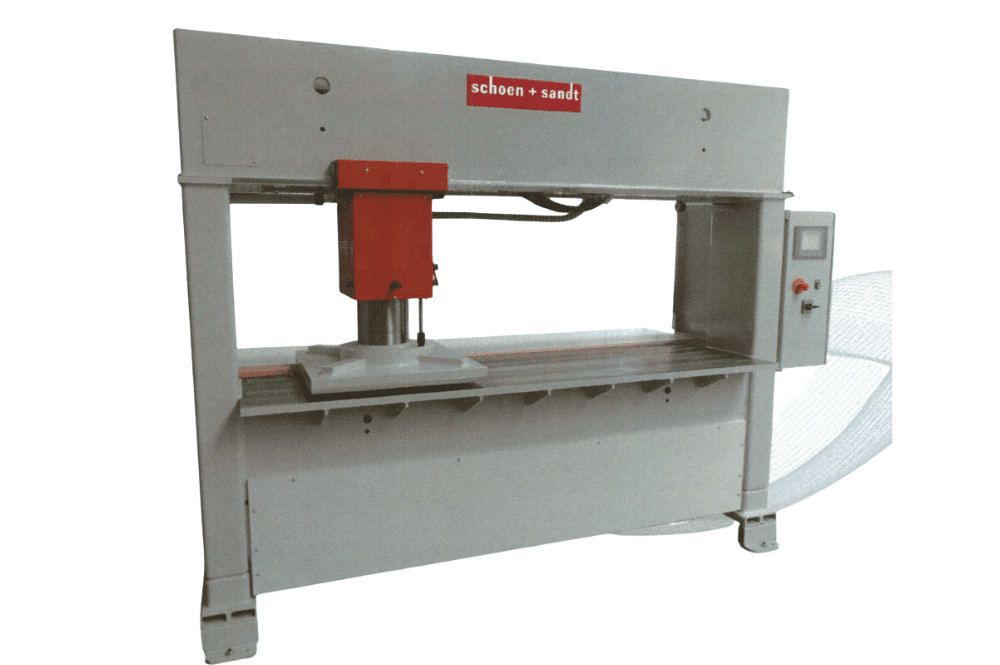

Electro-hydraulic Cutting & Embossing Press, Model 5230

Title

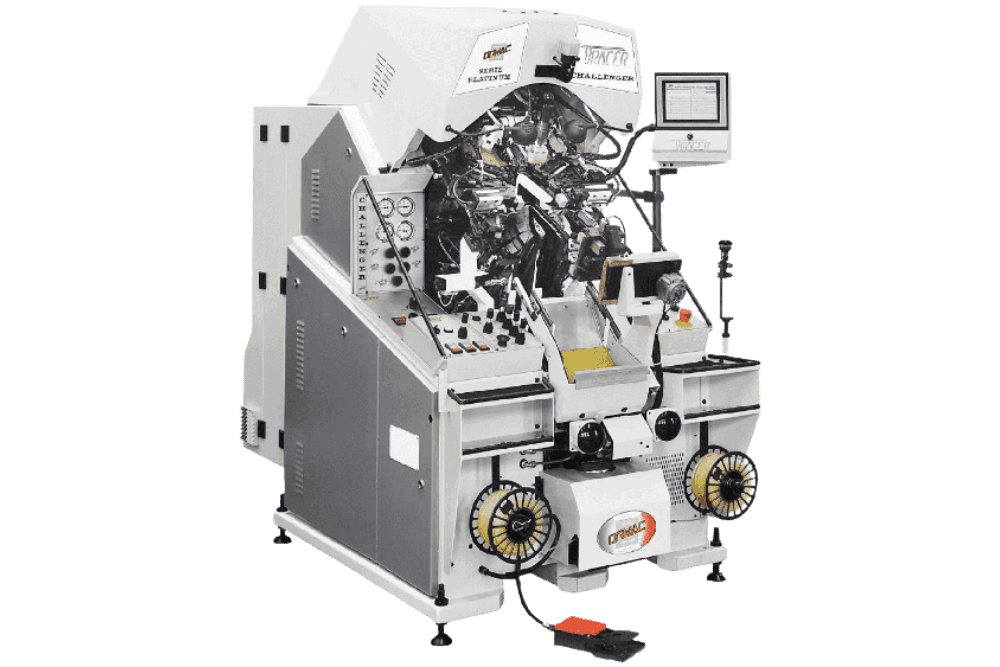

Electro-hydraulic Crosshead Die Cutting Machine, Model 7072M

Die Cut Machine For Paper

Die-cutting really does cover a very wide range of techniques, but when applied to the craft industry, it indicates the use of a machine to quickly and efficiently cut out numerous identical designs, mostly on paper materials. You don’t need any special tools like various types of specialized scissors, overly expensive stencils, or a small and unhandy craft knife to make several copies of the same shape in the same size. Time is saved and quality is maintained when standard shapes are cut out repeatedly.

Paper, chipboard, which is like cardboard but much thicker and dense, cloth, and other materials can be cut to precise shapes with the help of die-cutting machines, often known as card-making machines. Personal die-cutting machines, about the size of a toaster oven, are common among die-cutters. These tools are compact enough to fit on a craft desk or workspace or to be stashed away out of sight until needed. Die-cutting machines come in several brands, each with its own unique features.

A sheet of paper is put on the die cutter’s platform in manual machines. The paper is then placed on top of a die in the desired form. After positioning the die where you want the cut to be made, you fold, commonly referred to in the industry as “sandwich” the paper and die between two pieces of plastic. When the platform is in the correct position, a hand crank moves it through the machine. The metal die is pressed into the paper by applying uniform pressure to the mat as the platform moves through the machine. The die’s pointed edges slash through the paper, leaving the desired impression. The platform exits the opposite side of the machine, and you remove the transparent pad on top to see the die, paper, and finished product.

If you are considering or actively seeking a die-cutting machine, you likely have some inquiries. A die-cutting machine, typically known in the die-cutting industry as a card manufacturing machine, has been a game-changer in the crafting world. A lot of people’s lives are altered because of it. A crafter may feel nervous or hesitant about buying a die-cutting machine due to the machine’s significance, the complexity of its setup, and its high cost.

In the context of card-making, “die-cutting” refers to a process in which various metal forms, known as dies, are used to cut out pieces of paper, card, or even fabric. Every time you press down on the die, the sharp edge will slice cleanly through the material, leaving you with a perfectly die-cut shape, phrase, or design.

Here are some things to consider when purchasing a die-cutter. Take some time to consider your requirements. Think about the scope of your endeavors. Figure out where you can make some cuts. Take a look around the area. It’s true that investing in a die-cutting machine is a substantial outlay of cash, but the benefits it provides are immense. The way you do crafts will never be the same again, and you’ll have more options for personalization and originality in whatever you make.

The following machinery is available by us and suitable for the Envelope Industry:

Swing Arm Clicking Machines, Models SA22, SA27 & SA27L

Hydraulic Automatic Die Cutting Machine, Model 2070

Electro-hydraulic Automatic Crosshead Die Cutting Machine, Model 2071BZ

Electro-hydraulic Cutting & Embossing Press, Model 5230

Electro-hydraulic Crosshead Die Cutting Machine, Model 7072M

Opening Hours

Latest News & Articles

A Look Back to the History of the Shoe Lasting Machine

Mar 14, 2023

A Brief Guide to the Shoe Making Process

Feb 14, 2023

10 Types of Fiberglass, Their Uses, and Their Benefits

Jan 23, 2023

Die Cutting for Manufacturing-What You Need to Know

Jan 11, 2023