Footwear Machinery

Shoe Machinery

Historically, shoes were produced by hand by experienced artisans using conventional methods. In more recent years, a more advanced an innovative category of shoemaking machines has been developed. The introduction of cutting-edge computer programs and manufacturing equipment has made shoe design a great deal less complicated in recent years. The production of more shoes of higher quality in a shorter length of time is made possible by using the latest shoemaking equipment that is currently available from American Shoe Machinery Company. These days, designers sketch out their concepts for new footwear using computer-aided design applications.

The use of modern techniques and software enables our manufacturers to create products that are more aesthetically pleasing, affordable and still amazing quality. The grading of patterns and the development of logos are only two of the countless stages in the manufacture of a pair of shoes that can be done with the least amount of bother and time commitment possible. There are many other steps as well. Additional instances of these steps include the following: With the use of a machine that is intended solely for the production of footwear, the final product’s design can incorporate an extensive range of distinct patterns and textures. The production of shoes and other types of footwear requires the use of molds, dies, and presses, all of which are crucial components.

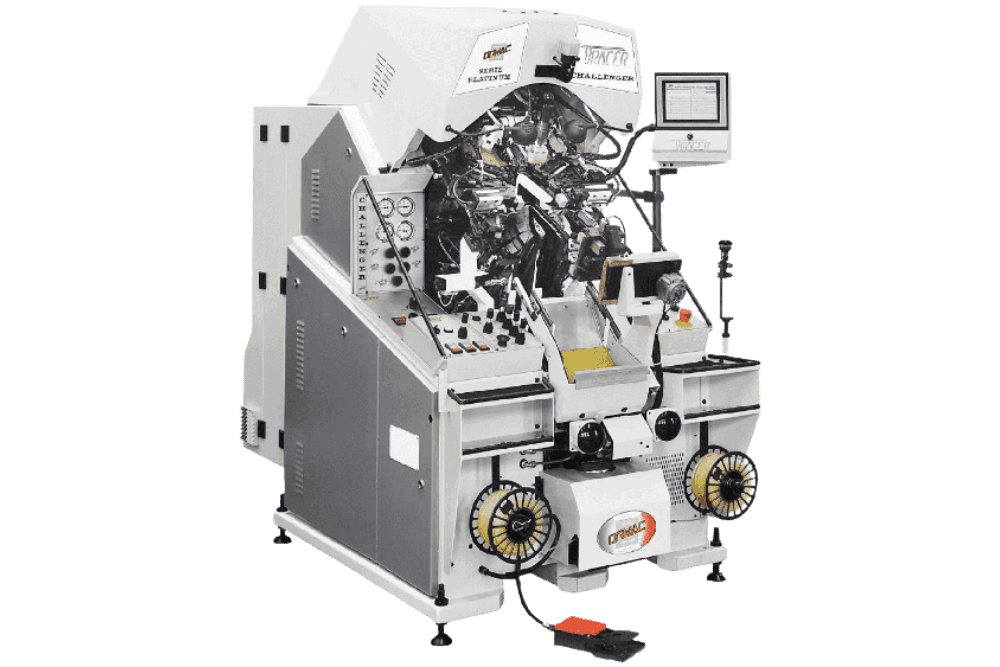

Machines that are used in the production of shoes can include those that are used to make the sole, the insole, and several other components. These machines also perform assembly and stabilization of the separate elements to create a finished pair of shoes from the components that make up the shoe. By utilizing these machines, manufacturers can modify the produced footwear in terms of its shape, size, design, and pattern. Cutting machines, pattern makers, sewing machines, lasting machines, closure machines, bottoming machines, finishing machines, insole-producing equipment, and repair machines are just some of the many machines used in the footwear industry. Other devices include bottoming machines, closure machines, and finishing machines.

Rapid shifts in both lifestyle and fashion drive up demand for a wide variety of shoe styles. To streamline production and raise standards, shoe factories are buying and installing footwear-making machinery. This, in turn, increases the need for machinery used in the production of shoes. In addition, rising wages and consumer confidence drive spending on footwear and, by extension, footwear production equipment. To further improve the manufacturing process, numerous shoe companies are purchasing footwear-making equipment that is equipped with cutting-edge technologies. The market for machines used in making shoes is growing as a result. The technology and machines used to make shoes have advanced considerably in recent years, which has helped boost output and cut down on processing times. Forecasted footwear manufacturing equipment demand growth drivers include the following. Initial startup costs for footwear factories and general manufacturing sector unpredictability are likely to slow market expansion. Growth in domestic manufacturing is likely to be a lucrative potential for smaller firms in developing countries.

Segmentation of the worldwide footwear manufacturing machinery market is done based on solution, machine type, and geography. Products and services associated with machinery used in the production of shoes are grouped together under the “Solutions” heading. Separate subcategories within this category include cutting machines, lasting machines, shoe stitching machines, closure machines (upper assembly), bottoming machines, finishing machines, and others (insole-making machines, managing & handling machines, and shoe repair machines). Under the service umbrella, you’ll find the sub-sectors of upkeep and repairs. Manual machines, semi-automatic machines, and fully-automatic machines all have their own segments within the market. Semi-automatic machines are expected to maintain their lead over fully-automatic machines in the worldwide footwear manufacturing machines market during the course of the forecasted time period.

In an industry in which fashion and market trends change at such a breakneck pace, having shoemaking machines that are able to develop and adapt at the same rate as the market and fashion is a crucial prerequisite. With the support of our machinery, you will be able to take your factory that makes shoes to the next level, and you will be prepared for anything that may come your way. Because our machines were designed by skilled artisans to be intuitive and simple to comprehend, becoming an expert in their operation won’t take nearly as much time as you might think it would.

Shoe construction might look very different from one style to the next, yet every shoe has a sole, insole, outsole, midsole, heel, and upper. Shoes may also have a lining, tongue, quarter, welt, or backstay, although these extra components depend on the style. Making and assembling the many components of a pair of shoes requires a wide range of specialized machines. Manufacturing shoes in a factory is much faster than doing so by hand, despite the high number of processes and components required. Modern factories use a manufacturing procedure called nesting, which splits up the multiple phases of shoe production amongst several distinct departments inside the plant, to increase efficiency. Departments including design, cutting, machining, sewing, assembly, and finishing all have titles that represent the work they do. Numerous machines are used, each with a specific function, but many people are also needed to ensure the process runs properly.

These days, shoes are made from a mind-boggling variety of materials. There is a continued demand for materials such as leather, plastic, cotton, and rubber. Ethylene vinyl acetate, polyurethane foam, and gel or liquid silicone are some examples of the innovative materials that can be found in today’s shoes, which were made possible by technological advancements. Do you think the steps involved in making shoes are a little bit too complicated? To make a pair of shoes in today’s market, there are undoubtedly a great number of processes, machinery, and people involved. Don’t forget, though, that there is one more factor that makes things just a tad bit more challenging: each and every shoe design also needs to be created in a wide variety of various sizes!

We offer Shoe Machinery for Cutting, Fitting, Stockfitting, Lasting, Bottoming and finishing as well as high quality replacement parts and merchandise. Additionally, we manufacture and offer machines and replacement parts for the Goodyear Welt Construction.

Replacement Parts & Merchandise

Awls

Cement Rolls

Cutters

Drivers

Knives

Needles

Sharpening Stones

Tru-Fit® Shank Material

We would be happy to assist you with product information and pricing. Please contact us for more information.

Opening Hours

Latest News & Articles

A Look Back to the History of the Shoe Lasting Machine

Mar 14, 2023

A Brief Guide to the Shoe Making Process

Feb 14, 2023

10 Types of Fiberglass, Their Uses, and Their Benefits

Jan 23, 2023

Die Cutting for Manufacturing-What You Need to Know

Jan 11, 2023