Gasket Industry

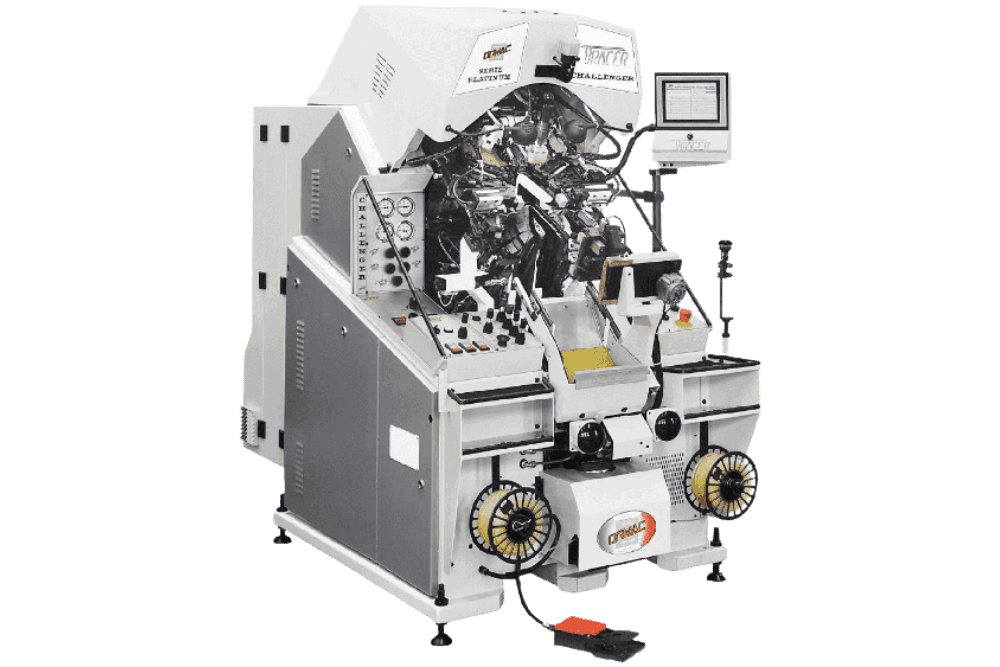

Swing Arm Clicking Machines, Models SA22, SA27 & SA27L

Hydraulic Swing Arm Cutting Machine, Model 1028C

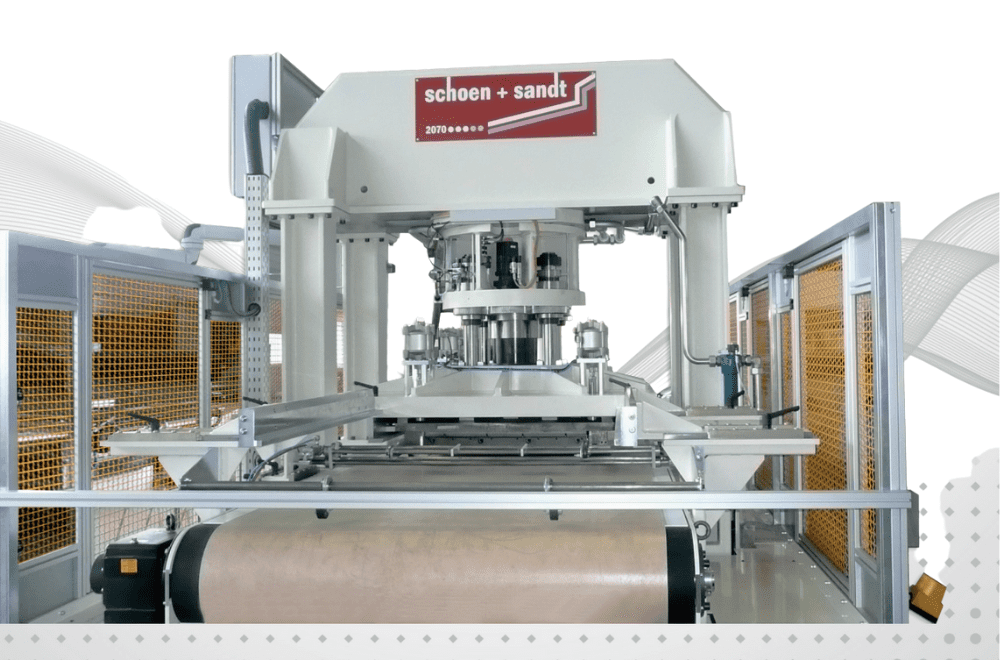

Hydraulic Automatic Die Cutting Machine, Model 2070

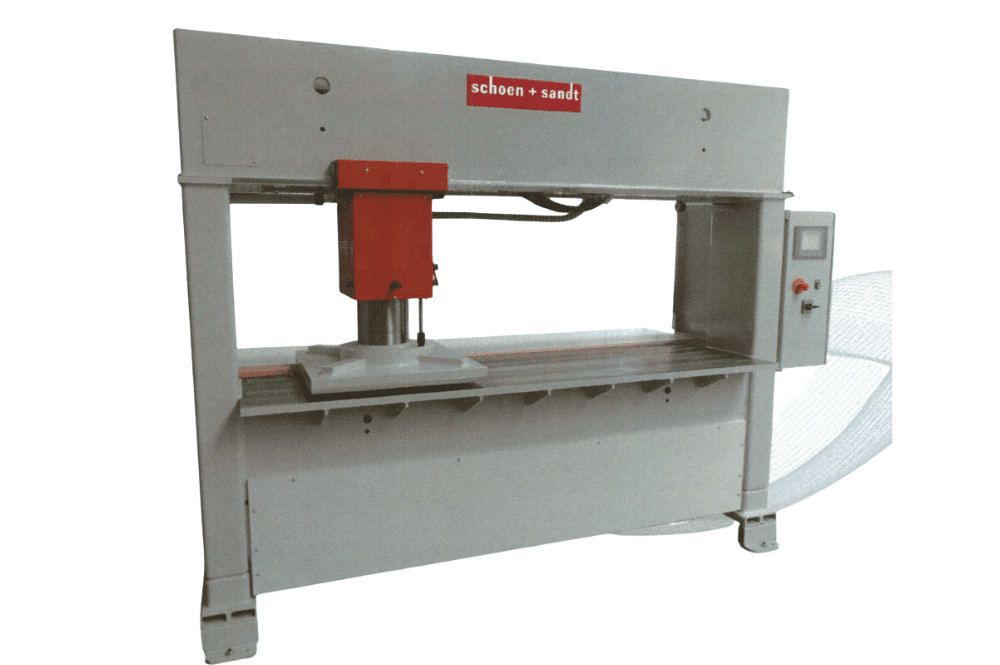

Hydraulic Upstroke Cutting Machine with receding beam, Model 5300

Hydraulic Die Cutter, Model 6005ba

Electro-hydraulic Crosshead Die Cutting Machine, Model 7072M

Gasket Die Cutting

Die-cut gaskets are used to prevent air and moisture from leaking between two flat surfaces. A die-cut gasket will close the space between the two surfaces when a sufficient bolt load produces a compressive force. In addition to preventing leaks, the seal can also be used to correct design flaws and application mistakes by filling irregularities on the contact surface.

Gasket die cutting has a wide range of potential uses across many different markets and sectors. Die-cutting for the electrical, lighting, and electronics manufacturing industries would be examples of some of the most popular businesses that currently make use of die-cut gaskets. In addition to the automotive and aerospace industries, the plumbing and medical fields are also among those in which we have observed a significant increase in demand for gasket die-cutting equipment.

Before deciding on a material for your die-cut gasket, you need to look into a few different factors. If the gasket will be used in a high-temperature environment, your material choices will be limited. Die-cut gaskets are ideal, but you should choose a different material if your system’s operating temperatures are going to be close to their maximum continuous working temperature. Think about the application’s internal fluid pressure. If your application will be subjected to high pressure, you should use a robust gasket material. Keep in mind the various gases and liquids that your gasket will need to seal. Gasket material should be selected with care to ensure it is chemically compatible with all of the application’s components. Count, measure, and inspect the bolts that will compress the gasket’s sealing surface area. It is well-known fact that different gasket materials would work better for different types of needs. The versatility in material need could be similar to that found in the leather industry.

Any material can be used to make die-cut gaskets, which can then be quickly cut using a die cutter. Sheet and roll forms of sealing material are commonly available from most suppliers. We can produce anything from a single die-cut gasket prototype to an extensive manufacturing run. Compressed sheet gaskets, cloth inserted gaskets, fabric, paper, felt, chipboard, a wide variety of textiles, fiberglass, foil, ethylene propylene, nitrile, sheet stock, and cork are all possible gasket materials.

Although there are many options when it comes to die-cut gaskets, it is crucial that you select the best possible product for your needs. We’ve found through the years that some are better suited for high-pressure applications, while others are more effective at water sealing. Watertight joints are best sealed with rubber gaskets, whereas ring joints benefit from metal gaskets. On the other hand, spiral wound gaskets excel in environments with both high heat and pressure. Compressed sheet gaskets or fiber-reinforced gaskets are the way to go if the applications you’re interested in involve low to medium-pressure levels. Ask yourself if the present materials you’re using will allow your product to reach compliance standards and enter new markets. Meeting compliance requirements, expanding your product’s reach into new markets, and determining whether or not we are the ideal partner to provide superior solutions for your gasket die-cutting needs.

The following machinery is available by us and suitable for the Gasket Industry:

Swing Arm Clicking Machines, Models SA22, SA27 & SA27L

Hydraulic Swing Arm Cutting Machine, Model 1028C

Hydraulic Automatic Die Cutting Machine, Model 2070

Hydraulic Upstroke Cutting Machine with receding beam, Model 5300

Hydraulic Die Cutter, Model 6005ba

Electro-hydraulic Crosshead Die Cutting Machine, Model 7072M

Opening Hours

Latest News & Articles

A Look Back to the History of the Shoe Lasting Machine

Mar 14, 2023

A Brief Guide to the Shoe Making Process

Feb 14, 2023

10 Types of Fiberglass, Their Uses, and Their Benefits

Jan 23, 2023

Die Cutting for Manufacturing-What You Need to Know

Jan 11, 2023